Inquiry

Form loading...

-

E-mail

-

Whatsapp

Choosing the right Trolly Crane for your needs can be a daunting task, especially with the variety of options available in the market. Trolly Cranes are essential tools in various industries, providing the capability to lift and transport heavy loads efficiently and safely. Understanding your specific requirements is crucial for making an informed decision; whether you are handling materials in a warehouse, managing construction tasks, or performing industrial lifting operations, selecting the appropriate Trolly Crane can greatly enhance your productivity and safety.

In this guide, we will walk you through the essential factors to consider when choosing a Trolly Crane. From load capacity and lifting height to power source and operational versatility, each aspect plays a critical role in ensuring that the Trolly Crane you select perfectly matches your operational demands. By carefully evaluating these features and understanding how they align with your applications, you can make a confident choice that optimizes performance and meets safety regulations.

In an ever-evolving industrial landscape, staying informed about the advancements in Trolly Crane technology is equally important. This guide aims to equip you with the knowledge to navigate the options available, empowering you to select a Trolly Crane that not only meets your immediate needs but also supports your future growth and efficiency goals.

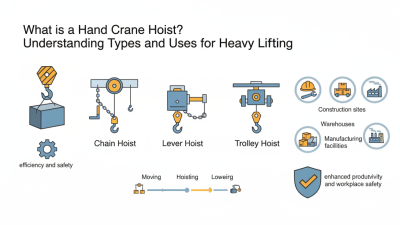

Trolley cranes are versatile lifting solutions used across various industries, each type designed to suit specific operational needs. Broadly, trolley cranes can be divided into several categories, including overhead trolley cranes, gantry cranes, and jib cranes.

Overhead trolley cranes are ideal for managing heavy loads in indoor environments, providing significant horizontal movement thanks to their bridge-like structure. Conversely, gantry cranes offer mobility, suitable for outdoor applications where lifting and moving large materials are essential, like construction sites or shipping yards. Jib cranes, with their fixed arm, cater to tasks requiring precise lifting in confined spaces, making them valuable in workshops and assembly lines.

Understanding the applications of these cranes is crucial for selecting the right equipment. Overhead trolleys are typically used in manufacturing plants for repetitive lifting tasks, whereas gantry cranes are favored for their portability in shipping and freight operations. Jib cranes serve specialized purposes, often in maintenance roles where flexibility and adaptability are needed. By assessing the specific requirements of your operation, such as load capacity, working environment, and movement range, you can determine which type of trolley crane will enhance your productivity and efficiency.

When selecting a trolley crane, several key factors must be considered to ensure that it meets the operational needs and safety requirements of your facility. First and foremost, understanding the load capacity is crucial. According to industry reports, the global demand for heavy lifting equipment is projected to grow at a CAGR of 5.6% from 2023 to 2028, underscoring the importance of choosing a crane that can handle your specific payload. Load capacities typically range from 1 ton to over 100 tons; therefore, accurately assessing your lifting needs will prevent overloading, which can lead to equipment failure and safety hazards.

Another vital consideration is the span width and lifting height of the trolley crane. These specifications must align with your structural workspace to maximize efficiency. A study published by the Occupational Safety and Health Administration (OSHA) reveals that improper crane configuration is a major contributor to workplace accidents, with up to 40% of all crane-related incidents attributed to mismatched operational parameters. Therefore, evaluating your existing infrastructure and selecting a crane with appropriate dimensions will help mitigate risks and enhance productivity.

Lastly, think about the mobility and control options available. As automation technologies advance, many cranes now offer features like remote operation and smart sensors to improve handling and reduce operator fatigue. Industry data shows that companies adopting technologically advanced lifting systems report a 25% increase in operational efficiency. Consequently, investing in a trolley crane that provides ease of use and incorporates modern safety features can significantly streamline your lifting processes and promote a safer work environment.

When selecting the right trolley crane for your operations, understanding load capacity requirements is crucial. According to the Crane Manufacturers Association of America (CMAA), the load capacity is one of the primary factors that determine the suitability of a crane for specific tasks. Industry standards suggest that the rated load should be determined by considering not only the maximum weight to be lifted but also the dynamic forces encountered during lifting, which can add significant stress to the equipment. Proper calculations should take into account factors such as the weight of the payload, potential shock loading, and the lifting height.

For instance, in a manufacturing environment, a report from the Occupational Safety and Health Administration (OSHA) indicates that over 40% of workplace injuries related to cranes involve improper load handling. This highlights the importance of selecting a crane that meets not just the static load requirements but also dynamic load factors for safe operation. Many operations find it beneficial to include a safety margin in their load calculations—commonly between 10-20%—to ensure that the crane can handle unexpected conditions without risking safety or equipment integrity. Hence, thoroughly assessing load capacity requirements helps in achieving optimal performance while minimizing operational risks.

| Crane Type | Load Capacity (tons) | Span Length (meters) | Lifting Height (meters) | Power Source |

|---|---|---|---|---|

| Electric Trolley Crane | 5 | 10 | 6 | Electric |

| Manual Trolley Crane | 3 | 8 | 4 | Manual |

| Hydraulic Trolley Crane | 10 | 12 | 8 | Hydraulic |

| Pneumatic Trolley Crane | 8 | 9 | 5 | Pneumatic |

When selecting a trolley crane, one of the most critical aspects to consider is the safety features and compliance standards. According to the Occupational Safety and Health Administration (OSHA), cranes are responsible for a significant number of workplace accidents. Ensuring that your trolley crane meets or exceeds safety standards can significantly reduce the risk of injuries. For example, cranes should have features such as overload protection, emergency stop buttons, and limit switches. These features are essential in preventing accidents and safeguarding your workforce.

When evaluating compliance standards, reference industry guidelines such as the American National Standards Institute (ANSI) and the Crane Manufacturers Association of America (CMAA). These organizations provide specifications detailing the safety requirements cranes must adhere to, which may include inspections, maintenance protocols, and operational safety measures. A report by the Industrial Truck Association indicates that integrating compliance checks can reduce incidents by up to 30%. It's vital to review documentation thoroughly and ensure that the trolley crane you plan to purchase aligns with these standards.

Tips: Always conduct a safety audit before operating a new trolley crane. Check for the presence of necessary safety features and ensure that your operators are adequately trained. Additionally, consider establishing a regular inspection schedule to maintain compliance and safety continuously. By proactively focusing on these aspects, you can significantly enhance the safety and efficiency of crane operations in your workplace.

When budgeting for the acquisition and maintenance of trolley cranes, it's essential to consider both initial costs and ongoing expenses. The upfront purchase price can vary significantly based on the crane's specifications, capacity, and features. Before making a purchase, it's wise to evaluate your specific lifting needs and the operational environment. A thorough assessment will prevent overspending on features that may not be necessary for your operations.

Tips: Always include a buffer in your budget for unexpected costs related to installation and initial setup. This may include modifications to your facility to accommodate the crane or additional safety equipment required for compliance with local regulations.

Maintenance costs also play a critical role in your budgeting process. Regular maintenance can prevent costly downtime and extend the life of the equipment. Create a maintenance schedule based on the manufacturer's recommendations and your usage levels. Allocate funds for routine inspections, replacements of worn parts, and emergency repairs to avoid any financial surprises down the line.

Tips: Consider establishing a maintenance reserve fund, where a small percentage of your operational budget is set aside specifically for unexpected repairs or maintenance. This proactive approach can help ensure you keep your equipment in peak operating condition without disrupting your overall financial planning.

This bar chart illustrates key metrics to consider when selecting a trolley crane, including capacity in tons, annual maintenance costs, and acquisition costs. Understanding these dimensions can help you make an informed decision tailored to your specific needs.