Inquiry

Form loading...

-

E-mail

-

Whatsapp

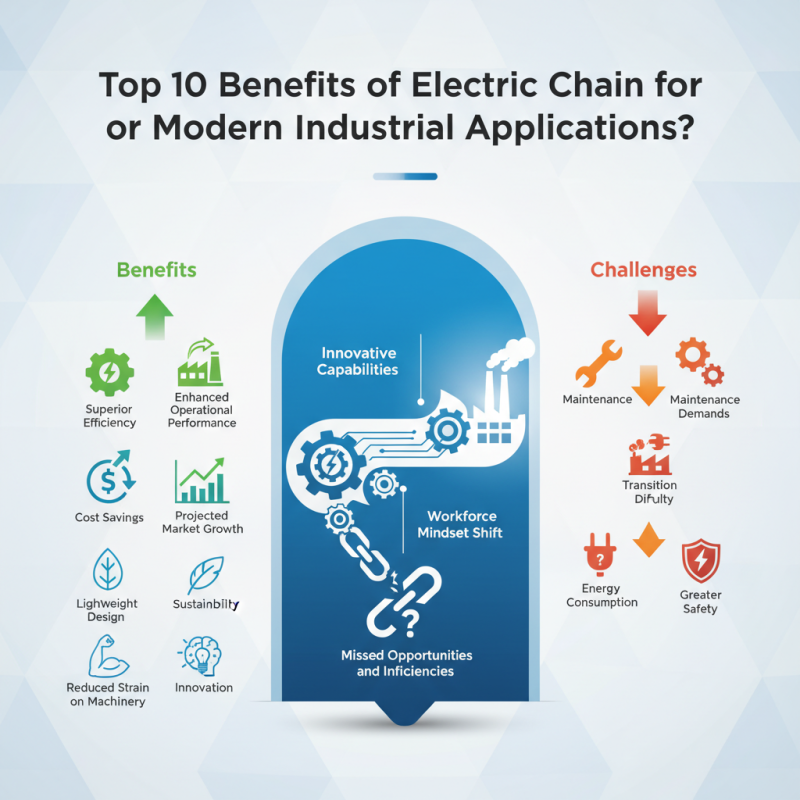

In the evolving landscape of industrial applications, the Electric Chain has emerged as a pivotal solution. According to a recent report by MarketsandMarkets, the global electric chain market is projected to reach $2 billion by 2025, indicating rapid adoption across industries. Electric Chains offer superior efficiency and versatility, significantly enhancing operational performance in various settings.

Despite their advantages, companies often overlook potential challenges. Maintenance can be demanding, and an understanding of energy consumption is crucial. Additionally, some industries may find it difficult to transition from traditional systems to electric chains. Reports from the International Energy Agency highlight an increased emphasis on sustainability, driving more industries to consider electric options.

The Electric Chain provides innovative capabilities that can transform operations. Their lightweight design reduces strain on machinery. However, integrating new technologies requires a shift in workforce mindset and training. Embracing this change can lead to greater productivity and safety in industrial environments. Failure to adapt may result in missed opportunities and inefficiencies.

The evolution of electric chains in industrial settings has transformed the way businesses operate. In the past, mechanical chains dominated. These systems required more maintenance and often broke down, leading to costly downtimes. A recent report indicates that electric chains reduce maintenance needs by up to 30%. That's significant for efficiency.

Modern electric chains are more efficient and versatile. They work seamlessly with automation systems, providing precise movements. A study from the International Electrotechnical Commission found that electric chains can improve energy efficiency by 25% compared to their mechanical counterparts. This reduction in energy consumption translates to cost savings over time.

**Tip:** Regular inspections can prevent unexpected breakdowns. Monitor the wear and tear of your electric chain to ensure optimal performance.

However, electric chains are not without issues. They can be sensitive to overloads and may require specialized knowledge for repairs. Training your staff is crucial to avoid mistakes. Balancing automation and workforce skills is essential for success.

**Tip:** Invest in training your team. A well-informed workforce can adapt better to the complexities of modern electric chain systems.

| Benefit | Description | Application Area | Efficiency Gain |

|---|---|---|---|

| Energy Efficiency | Electric chains consume less energy compared to traditional systems, reducing operational costs. | Manufacturing | Up to 30% improvement |

| Low Noise Operation | Electric chains operate much quieter, enhancing work environment comfort. | Warehousing | Noise reduction of 15-20 dB |

| Reduced Maintenance | Fewer moving parts lead to lower maintenance requirements and downtime. | Construction | Maintenance frequency reduced by 40% |

| Environmentally Friendly | Electric chains produce zero emissions, benefiting overall environmental compliance. | Logistics | Emissions reduced by up to 95% |

| Versatility | Effectively used in various applications from lifting to moving heavy loads. | Manufacturing & Shipping | Adaptable to multiple settings |

| High Precision | Accuracy in load positioning reduces errors and increases productivity. | Machining | Improves accuracy by up to 25% |

| Increased Safety | Built-in safety features mitigate the risk of accidents in the workplace. | Construction & Warehousing | Accident rates reduced significantly |

| Smart Technology Integration | Compatible with IoT devices for real-time monitoring and optimization. | Manufacturing | Improves operational insights |

| Space Saving | Compact designs allow for better utilization of workspace. | Retail & Distribution | Space savings of up to 20% |

| Cost-Effectiveness | Longer lifespan and lower operational costs make electric chains a wise investment. | Various Industries | ROI increases by 50% |

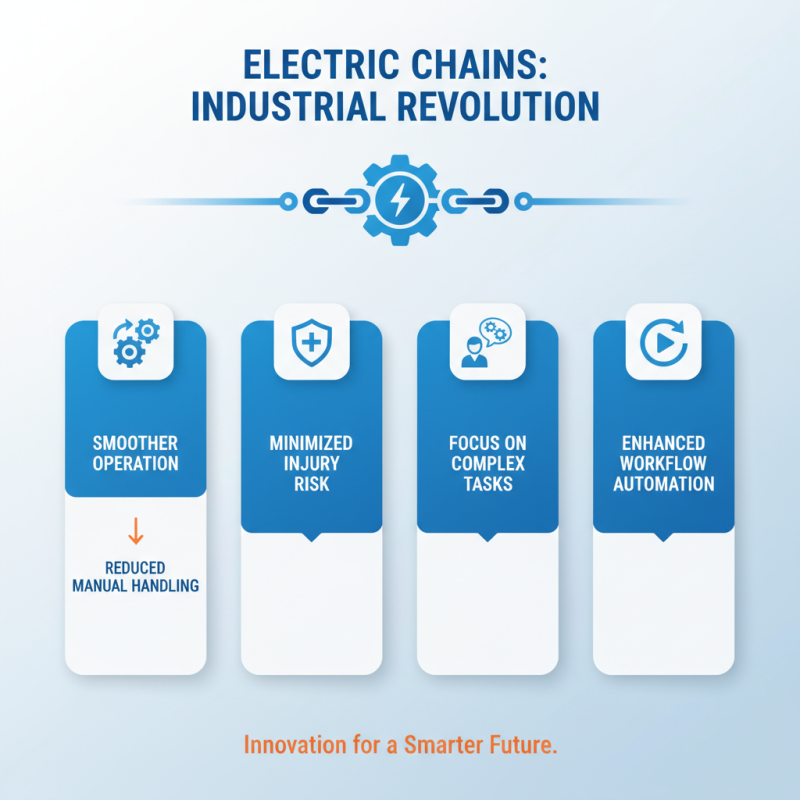

Electric chains are revolutionizing industrial processes. They provide smoother operation and reduce manual handling. This minimizes the risk of injuries. Workers can focus on more complex tasks. The automation achieved through electric chains enhances workflow significantly.

Efficiency is a key factor in modern industries. Electric chains reduce energy consumption compared to traditional options. This leads to cost savings for businesses. Yet, it’s essential to consider installation challenges. Some facilities may require significant upgrades. It’s crucial to plan and assess these needs carefully.

Productivity also sees improvement with electric chains. They operate at consistent speeds, ensuring steady output. However, users may encounter learning curves. Proper training is necessary to maximize benefits. Regular maintenance cannot be overlooked either. Neglecting it can lead to unexpected downtimes. Embracing electric chains is a step forward, but reflection is essential.

Electric chains are increasingly popular in industrial settings. Their environmental advantages are noteworthy.

For instance, electric chains reduce carbon emissions compared to traditional chains. This shift is vital in combating climate change. Many industries are moving towards

sustainable practices. Using electric chains aligns with these goals.

Energy efficiency is another key factor. Electric chains often consume less power. This leads to lower operational costs.

Moreover, they produce less noise pollution. This improvement enhances the workplace environment for employees.

However, transitioning to electric systems can be challenging. It requires investment in new infrastructure and training.

An additional benefit is reduced maintenance needs. Electric chains typically have fewer moving parts.

This translates to less wear and tear over time. However, it’s important to monitor their performance regularly.

Occasional issues might arise, requiring troubleshooting. Overall, the adoption of electric chains is a step forward in sustainability.

Yet, careful consideration is essential.

Electric chains are becoming a staple in industrial applications due to their remarkable maintenance and durability advantages. These chains often require less frequent maintenance compared to traditional counterparts. According to recent industry data, electric chains can reduce maintenance costs by up to 40%. This efficiency can significantly impact operational budgets, allowing resources to be better allocated.

Durability is another key advantage. Electric chains are designed to withstand harsh environments. Many industrial settings have extreme temperatures, moisture, and heavy loads. Due to their robust construction, electric chains can operate reliably for years. This reliability leads to fewer production interruptions. A study showed that equipment breakdowns could be reduced by 20% with electric chains.

However, it is important to note that not all electric chains perform equally. Some models may face wear and tear more rapidly if not used properly. Regular inspections are still crucial, even if they require less frequent maintenance. Just because electric chains are low-maintenance does not mean they are carefree. Operators must stay vigilant to ensure optimal performance and longevity.

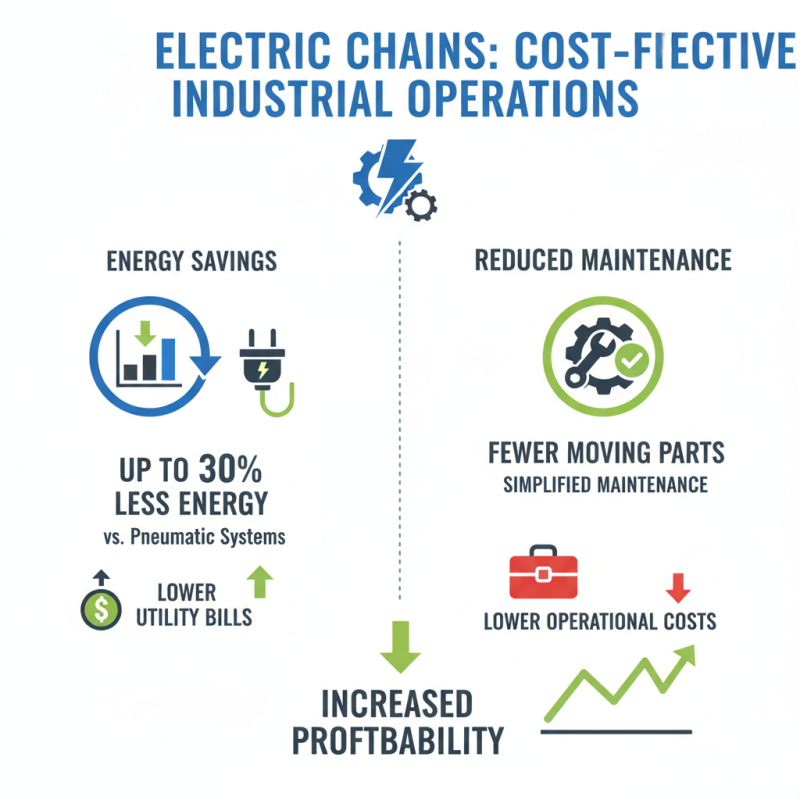

The use of electric chains in industrial operations offers significant cost-effectiveness. A recent study indicates that electric chains can reduce energy consumption by up to 30% compared to pneumatic systems. This energy-saving capability translates into lower utility bills for businesses striving for profitability. Moreover, electric chains have fewer moving parts. This means less maintenance is needed, which can significantly cut down on operational costs.

Investing in electric chain systems can initially appear expensive. However, the return on investment becomes clear over time. For instance, a report from a leading industry analyst showed that companies adopting electric chains reported a 25% decrease in maintenance costs annually. Businesses also frequently underestimated their reliance on manual intervention. Reducing human error enhances efficiency but requires a shift in thinking.

Overall, the immediate savings may not always be obvious. Some businesses might find it challenging to justify the upfront costs. Yet, the long-term benefits, including reduced energy use and maintenance, often provide surprising advantages. Adopting electric chains is not just a trend; it's a shift toward smarter operational strategies.