Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the rapidly evolving landscape of material handling, the emergence of Hydraulic Cargo Lifts is redefining efficiency and safety in logistics operations. According to industry expert Dr. Sarah Johnson, a leading authority on automated handling solutions, "The integration of Hydraulic Cargo Lifts in warehouses not only enhances productivity but also significantly reduces the risk of injuries associated with manual lifting." This statement underscores the transformative impact that advanced lifting technologies are expected to have in 2025, as businesses seek more effective ways to manage their material handling processes.

The benefits of Hydraulic Cargo Lifts extend beyond mere functionality. They play a crucial role in optimizing space utilization within facilities, allowing businesses to maximize their operational layout while ensuring the smooth transport of goods between different levels. Furthermore, the durability and reliability of these systems make them essential for industries looking to maintain a competitive edge in an increasingly demanding market. As we delve deeper into the top benefits of Hydraulic Cargo Lifts for efficient material handling, it becomes clear that they are not just a mechanism for lifting; they are a strategic investment towards innovation and excellence in logistics management.

Hydraulic cargo lifts are revolutionizing the efficiency of material handling in modern warehousing environments. One of the primary advantages of these systems is their ability to transport heavy loads with minimal manual effort. This not only reduces the risk of workplace injuries but also enhances productivity by allowing workers to focus on other tasks while the lift handles heavy lifting. The intuitive design of hydraulic systems ensures that loads can be raised or lowered smoothly, minimizing the chances of damage to both the goods and the facility itself.

Moreover, incorporating hydraulic cargo lifts into warehouse operations facilitates better space utilization. These lifts can be strategically installed to connect different warehouse levels, maximizing vertical space and reducing the need for extensive floor layouts. This vertical efficiency is particularly crucial in an era where urban warehousing is becoming more prevalent. By streamlining the flow of materials between floors, warehouses can manage inventory more effectively and respond rapidly to changing demand, ultimately leading to improved service levels and operational flexibility.

Hydraulic cargo lifts have revolutionized material handling, particularly in 2025, by incorporating enhanced safety features that protect both workers and cargo. One of the standout features is the automatic overload protection system, which prevents the lift from being operated under excessive weight, thereby reducing the risk of mechanical failure. This technology not only safeguards the lift but also minimizes the chances of accidents caused by overloading, ensuring a safer work environment.

In addition to overload protection, hydraulic cargo lifts are equipped with advanced emergency stop systems and safety barriers that engage if someone is too close to the lift during operation. These features significantly reduce the likelihood of injuries concerning pinch points and operational mishaps. Furthermore, many hydraulic lifts now come with monitoring systems that alert operators of any potential issues, allowing for preventative maintenance and immediate action if necessary. This focus on safety enhances operational efficiency by decreasing downtime and ensuring that the material handling process is both effective and secure.

Hydraulic cargo lifts have revolutionized material handling processes across various industries, significantly enhancing productivity. In 2025, the adoption of these lifts is projected to increase by 15%, as organizations seek more efficient ways to manage the movement of goods. According to a recent industry report by Material Handling Industry Association, businesses that utilize hydraulic lifts experience a 30% reduction in labor costs attributed to faster loading and unloading times. This efficiency not only streamlines operations but also minimizes potential delays, allowing companies to meet tight deadlines and improve customer satisfaction.

To maximize the benefits of hydraulic lifts, businesses should consider regular maintenance schedules, which can lead to a reduction in unexpected downtime by up to 40%. Additionally, training employees on proper operating procedures is essential; companies that invest in training see a 25% improvement in lift handling efficiency. Implementing a comprehensive safety protocol is equally important, as it not only protects workers but also enhances overall productivity through fewer accidents and disruptions.

Tip: When selecting a hydraulic cargo lift, prioritize models with adjustable height capabilities to accommodate a variety of loads and minimize the likelihood of mishandling. This adaptability not only boosts efficiency but also contributes to a safer working environment.

| Benefit | Description | Impact on Productivity | Efficiency Improvement (%) |

|---|---|---|---|

| Space Optimization | Hydraulic lifts maximize vertical storage, reducing floor space usage. | Allows for more materials to be stored in the same area. | 20% |

| Safety | Reduces the risk of injury by lowering manual handling of heavy loads. | Improves workplace safety and reduces insurance costs. | 15% |

| Speed | Enhances the speed of material transfer between levels. | Decreases time spent on loading/unloading processes. | 25% |

| Versatility | Accommodates various load sizes and types, providing flexible handling. | Increases operational flexibility and adaptability. | 18% |

| Reduced Maintenance Costs | Hydraulic systems require less frequent repairs compared to mechanical systems. | Lower downtime leads to uninterrupted workflows. | 10% |

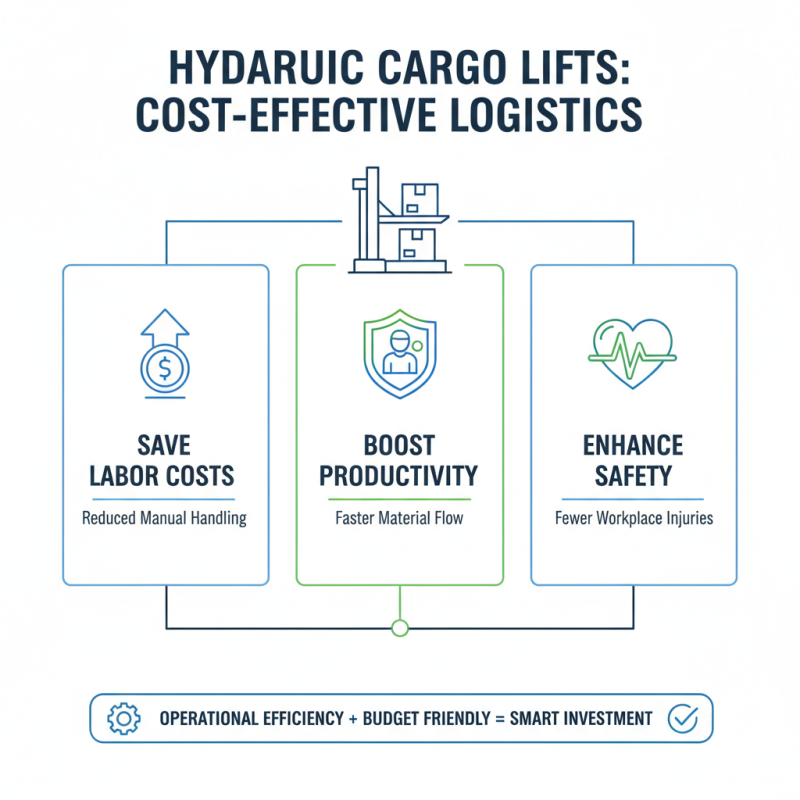

The cost-effectiveness of hydraulic cargo lifts in logistics has become increasingly prominent as businesses seek ways to enhance operational efficiency without straining their budgets. Hydraulic lifts streamline the material handling process, reducing the need for manual labor and minimizing the risk of workplace injuries. This not only leads to significant savings on labor costs but also enhances productivity, allowing companies to allocate resources more efficiently.

Moreover, hydraulic cargo lifts are designed to handle heavy loads with ease, effectively decreasing downtime associated with manual lifting or inefficient equipment. This reliability ensures that logistics operations can maintain a steady flow, which is crucial for meeting delivery deadlines and customer demands. The initial investment in hydraulic lifts pays off in the long run as they require less maintenance compared to other mechanical systems, further contributing to cost savings over time. Thus, choosing hydraulic cargo lifts is a strategic decision for organizations looking to optimize their material handling processes while keeping expenses under control.

In 2025, we can expect significant advancements in hydraulic cargo lift technology that will enhance efficiency and safety in material handling. With the continuous push for automation in industrial processes, the integration of smart sensors and IoT connectivity is anticipated to rise. According to a report by MarketsandMarkets, the global smart vertical lift industry is projected to grow by 30% annually, driven by the demand for real-time monitoring and data analytics in logistics operations. These innovations will not only streamline workflows but also reduce downtime by enabling predictive maintenance to prevent equipment failures.

Additionally, environmental sustainability will take center stage in hydraulic cargo lift design. As organizations increasingly commit to reducing their carbon footprints, many manufacturers are focusing on developing eco-friendly hydraulic systems. The adoption of biodegradable hydraulic fluids and energy-efficient systems can lead to a reduction in emissions by up to 20%, according to industry studies. Moreover, the implementation of energy recovery systems within hydraulic lifts allows for the reuse of kinetic energy, making the entire material handling process more efficient and less wasteful. As these trends unfold, hydraulic cargo lifts will play a crucial role in supporting the logistics industry's evolution toward smarter, greener operations.