Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the rapidly evolving landscape of materials handling, micro electric hoists have emerged as indispensable tools for both industrial and residential applications. Industry expert John Smith, a renowned engineer with over 20 years of experience in lifting technology, emphasizes the transformative power of these devices: "Micro electric hoists streamline operations by enhancing efficiency while significantly reducing manual labor risks." This insight encapsulates the core advantages that make micro electric hoists a go-to solution for lifting needs.

The compact design and advanced features of micro electric hoists allow them to effectively handle a range of lifting tasks in confined spaces—something traditional hoists struggle with. With their ease of operation and ability to lift heavy loads without extensive manpower, these hoists are not only increasing productivity but also improving workplace safety. As businesses and homeowners alike look for solutions to simplify their heavy lifting tasks, micro electric hoists are revolutionizing the way we approach lifting challenges.

In this discussion, we will explore the top benefits of using micro electric hoists, highlighting how these technologies can enhance operational efficiency and safety across various settings. From construction sites to home workshops, the versatility of micro electric hoists is set to redefine standard lifting practices.

Micro electric hoists have become indispensable in various modern lifting applications, offering numerous advantages over traditional lifting solutions. Their compact design allows them to fit into tight spaces, making them ideal for areas where larger equipment cannot operate. Additionally, these hoists are lightweight, which not only makes them easier to handle but also reduces strain on the operators. With their electric operation, micro electric hoists provide consistent power and reliability, allowing users to lift heavy loads efficiently and safely.

When considering the use of micro electric hoists, it's essential to keep a few tips in mind. First, assess the weight and dimensions of the loads you intend to lift to choose an adequately rated hoist. This will ensure safety and prevent equipment failure. Second, always check the power supply requirements. Ensuring compatibility will prevent operational issues and maintain efficiency. Moreover, regular maintenance is crucial to keep the hoist in optimal working condition and extend its lifespan.

The versatility of micro electric hoists is particularly beneficial in various industries, from construction to manufacturing and even home improvement projects. They can easily be utilized for lower lifting heights or in confined working environments. By incorporating micro electric hoists into lifting tasks, businesses and individuals can greatly enhance productivity while maintaining safety and efficiency in their operations.

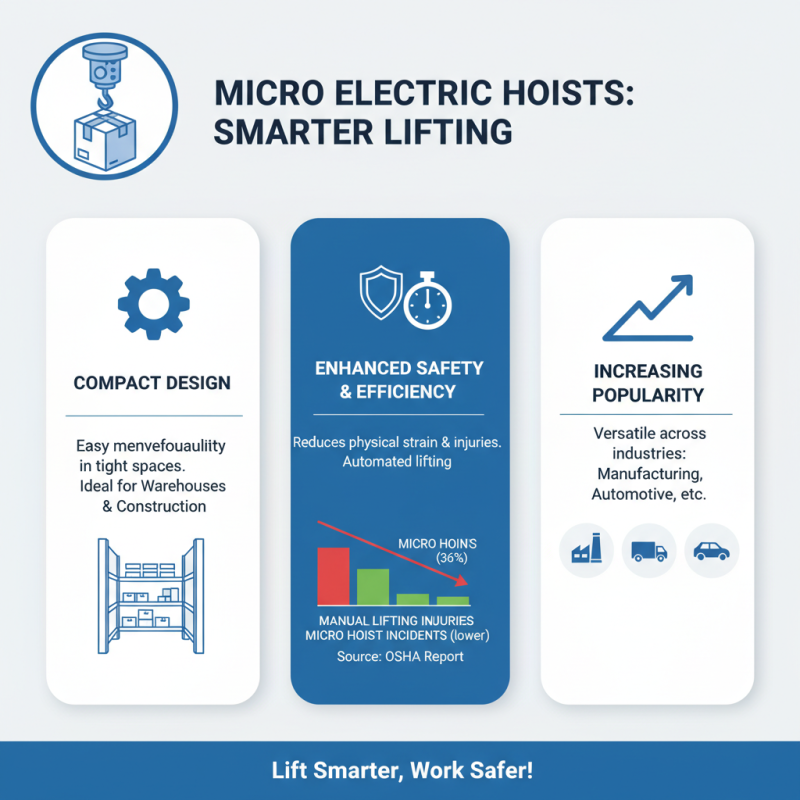

Micro electric hoists are becoming increasingly popular across various industries due to their unique features that significantly enhance both efficiency and safety in lifting operations. One key feature is their compact design, which allows for easy maneuverability in tight spaces—an essential factor in warehouses and construction sites. According to a report by the Occupational Safety and Health Administration (OSHA), nearly 36% of workplace injuries are caused by improper manual lifting practices. Micro electric hoists mitigate such risks by providing automated lifting solutions that reduce physical strain and the likelihood of injury.

Another important feature of micro electric hoists is their advanced safety mechanisms, including overload protection and automatic shut-off systems. These enhancements ensure that the hoist operates within its safe limits, effectively minimizing the potential for equipment failure. The Material Handling Industry of America has noted that implementing safer lifting technologies can decrease workplace accidents by up to 25%. Furthermore, micro electric hoists often come equipped with remote control capabilities, offering operators greater control and reducing the risk associated with close proximity to lifted loads. This combination of design and safety features highlights why micro electric hoists are essential tools for modern lifting needs, significantly boosting productivity while prioritizing worker safety.

Micro electric hoists have been gaining traction in various industries, primarily due to their efficiency and compact design compared to traditional hoisting systems. A comparative analysis reveals that micro electric hoists offer significant advantages, particularly in small-scale applications and confined spaces. According to a recent industry report by Allied Market Research, the global hoisting equipment market is expected to grow at a CAGR of 6.2% from 2021 to 2027, illustrating a rising demand for more versatile and compact lifting solutions. The lightweight nature of micro electric hoists allows for easier maneuverability, making them ideal for tasks in tight environments where traditional hoists may lack adaptability.

Moreover, when it comes to operational efficiency, micro electric hoists demonstrate superior performance in terms of speed and precision. A study by the International Organization for Standardization (ISO) indicates that micro electric hoists can improve lifting operation speeds by up to 30% compared to their traditional counterparts, which often rely on manual processes that are not only slower but also more prone to human error. The incorporation of advanced technologies, such as overload protection and remote control operation, enhances safety and reliability, further solidifying the micro electric hoist's position as a modern alternative. As industries continue to evolve, the shift towards adopting micro electric hoists over traditional hoisting systems is expected to persist, driven by the need for efficient, reliable, and space-saving solutions.

Micro electric hoists are versatile tools increasingly adopted across a range of industries due to their efficiency and ease of use. In construction, for instance, these hoists are utilized for lifting and moving materials to heights that would otherwise require extensive manual labor. Their compact design allows them to fit into tight spaces, making them ideal for both indoor and outdoor projects. Similarly, the manufacturing sector benefits from the quick and precise movements of micro electric hoists, which can streamline assembly lines and enhance overall productivity.

Moreover, the entertainment industry has found significant applications for micro electric hoists, particularly in the setup and dismantling of stages and lighting systems. Their ability to lift heavy equipment with minimal effort makes them indispensable for event organizers who need to ensure safety and efficiency when managing complex setups. Additionally, in the logistics field, micro electric hoists contribute to improving warehouse operations by facilitating the lifting and moving of heavy packages, thus reducing the physical strain on workers and enhancing operational workflows. This ability to adapt to diverse environments underscores the value of micro electric hoists in modern industrial applications.

To ensure the optimal performance of micro electric hoists, regular maintenance is essential. One of the key maintenance tasks is checking the hoist's power supply and electrical connections. Ensure that all connections are secure and free from corrosion or wear. This not only helps in maintaining efficiency but also prevents potential electrical failures. Additionally, regularly inspecting the hoist’s wiring and power cord for any signs of damage can significantly avoid accidents and prolong the lifespan of the equipment.

Another important aspect is to perform routine lubrication of moving parts. Proper lubrication minimizes friction, enhances performance, and reduces wear over time. Be sure to use the manufacturer-recommended lubricants and follow the guidelines on how often these should be applied. Additionally, inspecting the hoist's mechanical components—such as pulleys, hooks, and cables—for signs of wear and tear will help in identifying issues early on. Taking proactive steps ensures that micro electric hoists continue to operate safely and effectively, meeting all lifting requirements.

| Benefit / Maintenance Tip | Description | Frequency / Usage |

|---|---|---|

| Compact Design | Micro electric hoists are lightweight and easy to maneuver, making them ideal for tight spaces. | For small projects and regular lifting applications. |

| High Load Capacity | Despite their size, they can lift significant weights, providing efficiency without complexity. | Used for heavier lifting tasks as needed. |

| Energy Efficient | Designed to consume less energy compared to traditional hoists, reducing operational costs. | Ongoing, during every use. |

| Regular Lubrication | Ensures smooth operation and prolongs the life of moving parts. | Every month or after heavy use. |

| Safety Features | Includes features such as overload protection, ensuring safe lifting operations. | Always check before operation. |

| Routine Inspections | Regular checks for wear and tear to ensure safe and efficient operation. | At least once a month. |