Inquiry

Form loading...

-

E-mail

-

Whatsapp

Selecting the right Hand Crane Hoist can greatly impact your efficiency and safety during lifting tasks. The market offers various options tailored to different needs. Understanding these options can be overwhelming, especially with so many product features and specifications.

For instance, some hoists are compact and portable, while others provide heavy-duty performance. You might be tempted to choose the cheapest option, but this decision can lead to frequent repairs. A reliable Hand Crane Hoist often costs more upfront but saves money in the long run.

It’s essential to consider factors like weight capacity, lifting speed, and durability. Some users overlook these details, which can affect their operation. Each project has unique demands, and matching those needs with the right Hand Crane Hoist is crucial. As you explore the best options for 2026, reflect on your specific requirements to ensure you make a wise investment.

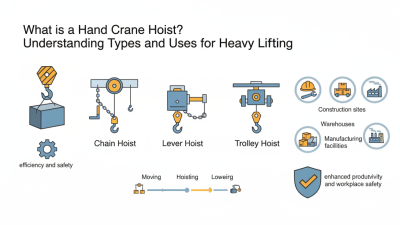

Hand crane hoists are essential tools in various industries. They help lift heavy loads in warehouses, construction sites, and manufacturing facilities. Understanding the types and applications of these hoists is vital for efficient operation.

There are several types of hand crane hoists. Manual chain hoists are popular for their simplicity and reliability. They require no electricity, making them versatile for indoor and outdoor use. On the other hand, lever hoists offer more control, ideal for heavy-duty operations. Some models include built-in safety features, but they can be heavier and less portable.

When choosing a hand crane hoist, consider your specific needs. Evaluate load capacity, lift height, and ease of use. However, it’s easy to overlook potential limitations, such as space constraints or operator training. Improper use can lead to accidents or equipment damage. Reflect on your choices carefully, as the right hoist can enhance productivity and safety.

| Type | Load Capacity (lbs) | Lift Height (ft) | Material | Applications |

|---|---|---|---|---|

| Manual Chain Hoist | 1000 | 10 | Steel | Construction, Garage |

| Electric Chain Hoist | 2000 | 15 | Aluminum | Factories, Warehouses |

| Pneumatic Hoist | 1500 | 12 | Composite | Automotive, Marine |

| Lever Hoist | 800 | 8 | Steel | Rigging, Lifting |

| Electric Wire Rope Hoist | 3000 | 20 | Steel | Construction, Heavy Machinery |

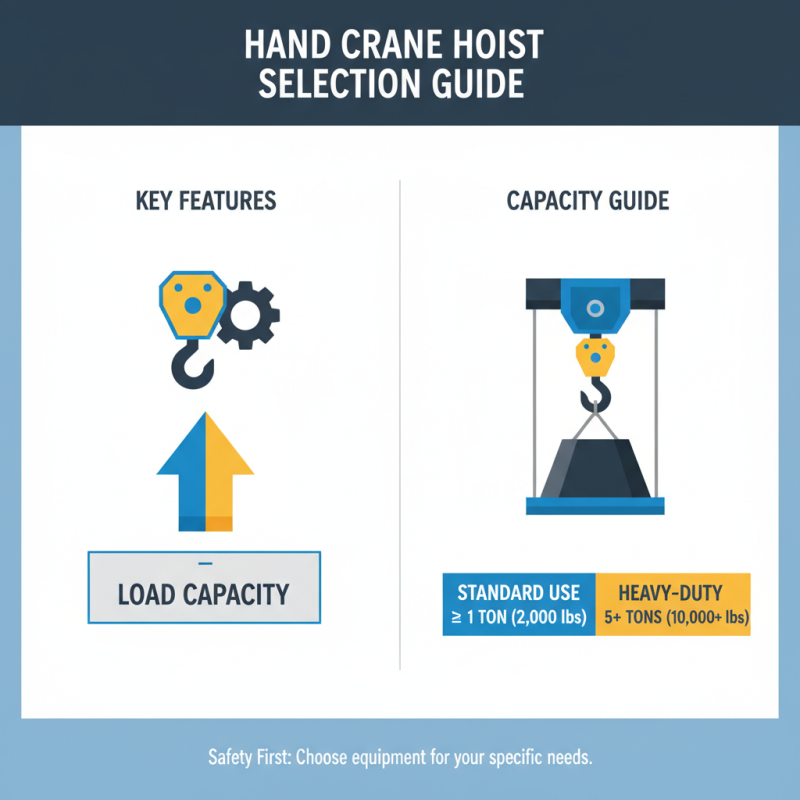

Choosing the right hand crane hoist can be challenging. Key features determine how effective and safe the equipment will be for your needs. Load capacity is crucial. A standard hand crane hoist should offer a maximum load of at least 1 ton. However, applications may require higher capacities, sometimes exceeding 5 tons.

Design is equally important. Look for hoists that are easy to operate. The ergonomic handle should allow for comfortable use during long tasks. Additionally, consider the lifting height. Many projects will require a minimum of 10 feet. Yet, some tasks may demand even greater height.

Safety features cannot be overlooked. A hoist should have an integrated safety latch and an overload protection system. Data shows that over 20% of accidents occur due to equipment failure. Therefore, investing in a high-quality hoist can significantly reduce workplace risks. These considerations are vital for finding the best hand crane hoist to fit specific job requirements.

In 2026, the market for hand crane hoists is expanding. When selecting a hoist, consider various factors. You need reliable lifting capacity, ease of use, and safety features. Many designs feature compact sizes. This allows for efficient storage when not in use. However, the weight limits can vary significantly. You should always check specifications before making a purchase.

Not all models are created equal. Some hoists excel in portability but lack the power needed for heavy loads. Others might offer excellent lifting capabilities but are more cumbersome to handle. Users often report frustration with complicated setups. Ensuring a smooth operation is vital in any lifting job. While many brands aim for innovation, consistency remains a challenge.

When evaluating options, safety should be your top priority. Look for hoists with reliable locking mechanisms. A hoist that slips can lead to accidents. Many users wish there were more user-friendly designs. There is a fine balance between function and usability. Some models also have feedback issues, making it hard to know when they are overloaded. Ultimately, finding the right hand crane hoist requires careful consideration of your specific needs.

When using hand crane hoists, safety is a paramount concern. According to industry research, approximately 50% of workplace accidents involve lifting equipment. This statistic underscores the need for proper safety measures. Users must ensure their hoists are rated for the specific weight they will lift. Overloading a hoist can lead to mechanical failure, posing serious risks.

Regular inspections are critical for maintaining safety. A study revealed that 30% of accidents occur due to equipment malfunction. Checking for frayed ropes, damaged hooks, and worn-out gears can prevent many of these incidents. Users often overlook routine maintenance, which can lead to dire consequences. Training is equally important. Operators should understand weight limits and proper lifting techniques.

Utilizing safety gear can mitigate risks significantly. Wearing helmets and using spotters can enhance safety during operation. However, some workers neglect these precautions. This carelessness can result in accidents that might have been avoided. Transparency in safety protocols is pivotal. The workplace must foster a culture where everyone prioritizes safety over speed.

This bar chart illustrates the weight capacity of various types of hand crane hoists available in 2026. It's important to consider the right type of hoist based on the weight needs of your project along with safety considerations when operating these hoists.

Hand crane hoists are essential for lifting and moving heavy loads safely. To ensure their longevity, proper maintenance plays a critical role. According to a study by the National Safety Council, regular inspections can decrease the likelihood of equipment failure by 30%. Ignoring maintenance is a mistake. It can lead to significant downtime.

Inspect the hoist regularly for wear and tear. Check the hooks and cables for fraying or damage. The Occupational Safety and Health Administration (OSHA) recommends conducting these checks at least once a month. Lubrication is key. Use the recommended lubricants to reduce friction and wear on moving parts.

Another important aspect is training. Operators must understand how to use the hoist properly. Lack of training can cause misuse, leading to accidents or equipment damage. The Bureau of Labor Statistics reported that improper usage accounts for 15% of workplace injuries involving hoists. Failure to adopt safety protocols can lead to costly repercussions, both financially and in terms of safety.