Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the construction and manufacturing industries, efficiency and safety are paramount. The Chain Block Crane is a vital tool for material handling. According to a report by Grand View Research, the global market for lifting equipment is projected to reach $22.3 billion by 2025. This growth highlights the importance of advanced cranes, like the Chain Block Crane, in improving productivity.

Industry expert John Smith states, "The Chain Block Crane maximizes lifting capabilities while ensuring operator safety." His expertise emphasizes the crane's essential role in everyday operations. These cranes are designed for heavy lifting, offering ease of use and versatility. Despite their advantages, proper training and maintenance are critical. This prevents accidents and optimizes performance.

As industries evolve, there is a need for innovation in lifting technologies. While the Chain Block Crane delivers reliable performance, ongoing evaluations are crucial. Companies must reflect on their use of these tools to ensure they meet current standards. Balancing efficiency with safety is an ongoing challenge. Embracing new technologies and strategies can enhance operational success.

A chain block crane, also known as a chain hoist, is a vital tool in various industries. It is designed to lift heavy loads safely and efficiently. These cranes utilize a chain mechanism to move payloads vertically or horizontally. According to industry reports, the global market for lifting equipment, including chain block cranes, is expected to grow significantly, fueled by rising construction activities.

The working mechanism of a chain block crane involves a manual or electric operation. Depending on the design, lifting can be executed using a hand chain or an electric motor. The chains are wound around a pulley system. While this mechanism is effective, it requires regular maintenance to ensure safety. Data suggests that over 30% of lifting accidents occur due to improper use or lack of maintenance.

In terms of specifications, chain blocks can lift from a few hundred kilograms to several tons. Various factors, such as load capacity and height of lift, play crucial roles in crane selection. Performance issues can arise if the equipment is overloaded. Maintenance records show that about 20% of chain block failures are due to neglect. Understanding these nuances is critical for effective usage.

| Feature | Description |

|---|---|

| Type | Manual or Electric |

| Load Capacity | Up to 10 tons |

| Lift Height | Up to 30 meters |

| Power Source | Electric or Manual Crank |

| Usage | Construction, Warehousing, Shipping |

| Safety Features | Overload Protection, Emergency Stop |

| Maintenance | Regular Lubrication and Inspection |

A chain block crane is a mechanical lifting device. It uses a simple chain and pulley system. This design makes it effective for moving heavy loads. Understanding its basic components is essential for safe operation.

One crucial part of a chain block crane is the chain itself. It is often made from durable steel. The chain loops around a sprocket, allowing for lifting and lowering of loads. The block is the next key component. It houses the pulleys and the chain. This block helps in distributing the weight evenly. Over time, the block can wear down. Regular checks are important to maintain safety.

Another essential piece is the hook. The hook secures the load during lifting. It's vital that the hook is not damaged. A broken hook can cause accidents. Additionally, the hand chain assists in manually operating the crane. Users should be cautious while using it. Improper use can lead to strain or injury. Proper training is needed to ensure effective handling of the chain block crane.

This chart illustrates the load capacity of chain block cranes based on different tonnage ratings. The values represent the maximum load that each type of crane can handle effectively.

A chain block crane, also known as a chain hoist, is a popular lifting device. It consists of a chain, a hook, and a simple mechanism. The operating mechanism is primarily based on friction and leverage. This makes it effective in various lifting tasks.

When the user pulls the chain, it engages the lift mechanism. The chain wraps around a cogged wheel, creating a mechanical advantage. This process allows a person to lift heavy objects with minimal effort. The design is compact and straightforward, making it accessible for both professionals and DIY enthusiasts.

However, using a chain block crane isn't without challenges. Improper use can lead to accidents. It's essential to check the load capacity before lifting. Forgetting to inspect the device can result in mishaps. Awareness of potential hazards is key to safe operation. Recognizing these details ensures a more effective lift.

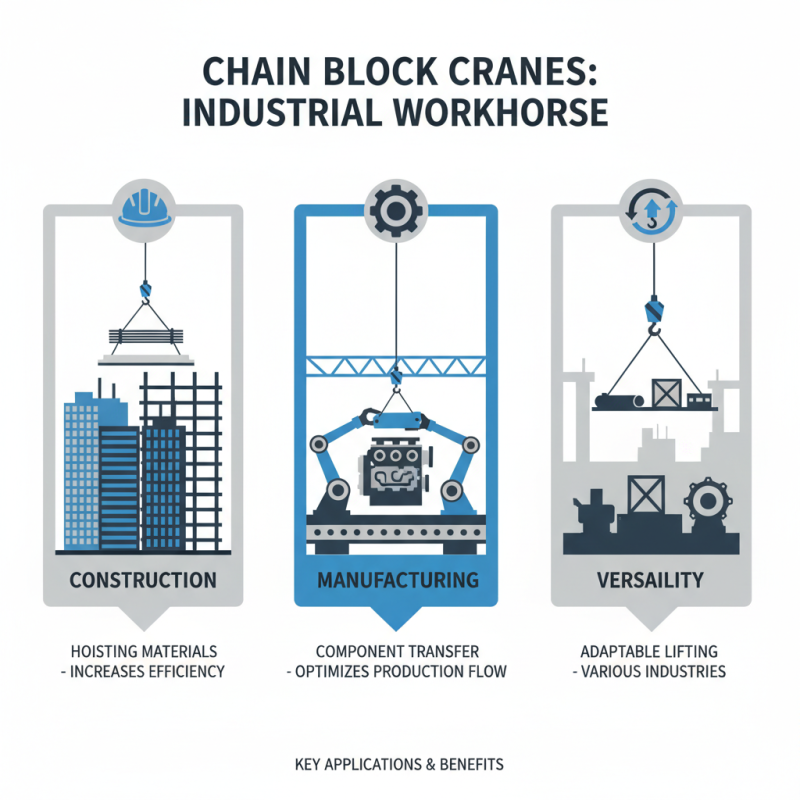

Chain block cranes play a crucial role in various industries. They are versatile lifting devices used for moving heavy loads. Construction sites frequently utilize these cranes for hoisting materials, making tasks more efficient. In manufacturing, chain block cranes assist in transferring components between different production stages.

In warehouses, these cranes provide solutions for inventory management. They can lift and position heavy pallets and machinery with ease. However, improper use can lead to accidents. Training operators is essential to ensure safety. Some workers may underestimate the importance of following guidelines, leading to potential hazards.

Additionally, chain block cranes find applications in entertainment, especially during stage setups. They help in arranging lighting and sound equipment efficiently. Yet, awareness of load limits is often forgotten. This oversight can create issues, affecting both the equipment and personnel involved. Continuous education and timely maintenance can enhance the safety and effectiveness of chain block cranes in these environments.

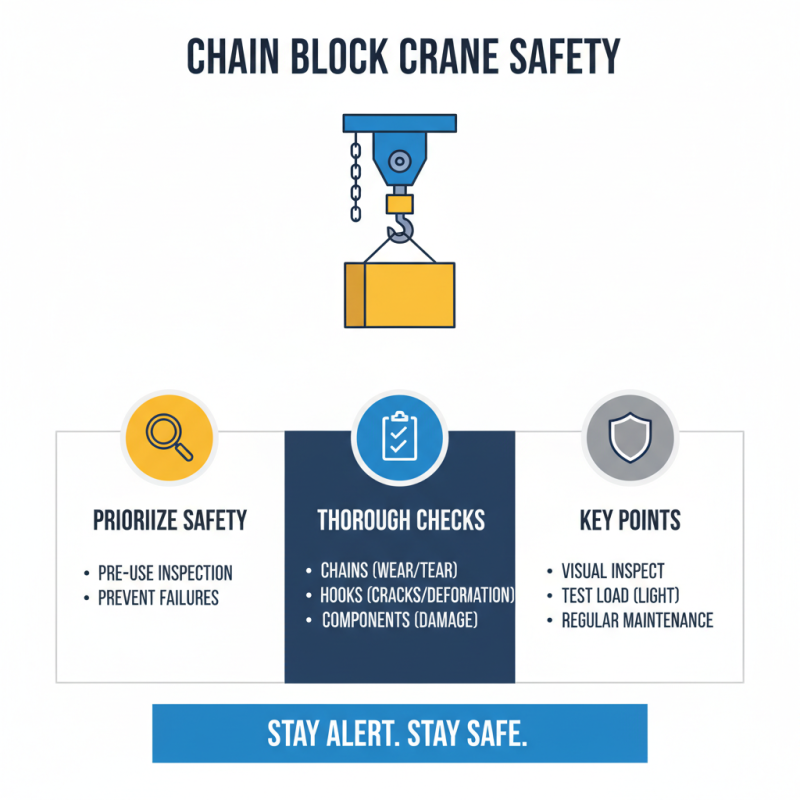

Chain block cranes are powerful tools for lifting heavy loads. However, safety must be prioritized when using them. Operators should conduct thorough inspections before each use. Check for wear and tear on chains, hooks, and other components. Look for any signs of damage that could lead to failures.

Proper training is essential for all users. Untrained operators may not understand how to handle loads securely. They might also fail to recognize hazards. This can lead to accidents. Always wear protective gear, including gloves and helmets. Safety signage should be visible to remind workers of potential risks.

During operations, avoid overloading the crane. Each model has a specific weight limit. Exceeding this can result in equipment failure. Additionally, keep the work area clear of unnecessary personnel. Distracted workers increase risk. Regular safety drills can prepare users for emergencies. Remember, safety is not just a guideline; it’s a commitment.