Inquiry

Form loading...

-

E-mail

-

Whatsapp

Choosing the right hydraulic hoist for your lifting needs is a critical decision that demands careful consideration of various factors. An industry expert, John Smith, a senior engineer with over 20 years of experience in the hydraulic systems sector, once stated, "Selecting the correct hydraulic hoist can significantly enhance efficiency and safety in any lifting operation." This perspective underscores the importance of understanding the range of options available and how they align with specific operational demands.

Hydraulic hoists are essential tools in various industries, enabling safe and effective lifting of heavy loads. However, with the multitude of choices on the market, the process of selecting the most suitable hoist can be daunting. Factors such as load capacity, lift speed, maintenance requirements, and operational environment must be evaluated meticulously to ensure optimal performance and safety. By doing so, businesses can significantly reduce the risks associated with lifting operations and improve overall productivity.

In the following sections, we will explore key considerations that should guide your decision-making process when choosing a hydraulic hoist. By understanding these critical aspects, you will be better positioned to select a hoist that meets your specific needs, ensuring safe and efficient lifting operations.

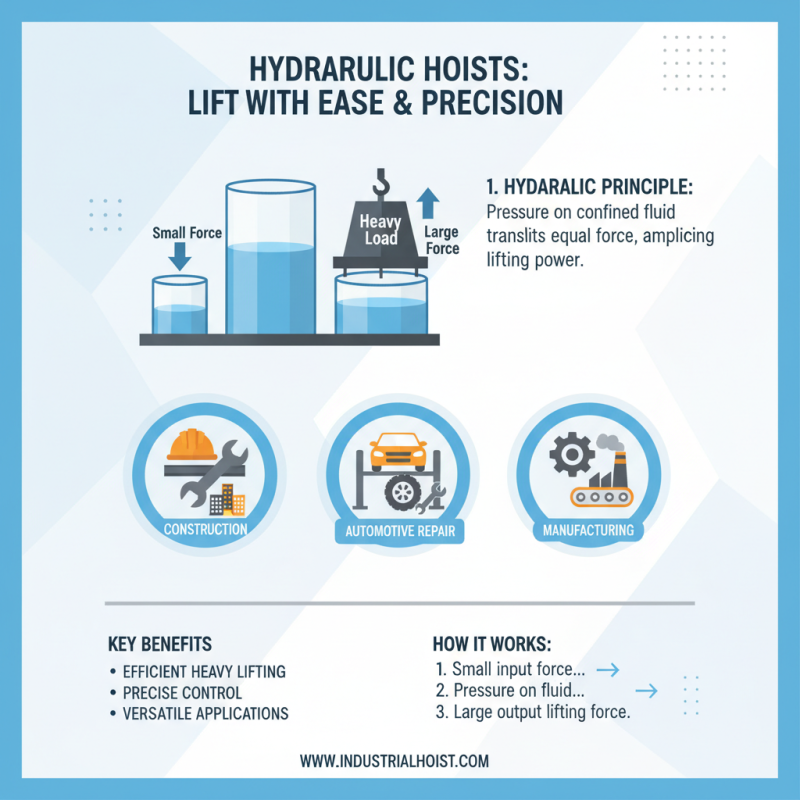

Hydraulic hoists are essential tools used in various industries for lifting heavy loads with ease and precision. Understanding their functionality begins with the basic principle of hydraulics, which utilizes incompressible fluids to transmit force. When pressure is applied to a fluid in a confined space, it generates an equal force in all directions, enabling the hydraulic system to lift weights much heavier than manual lifting methods. This efficiency makes hydraulic hoists particularly valuable in construction, automotive repair, and manufacturing sectors.

When selecting a hydraulic hoist, it is crucial to consider several factors, including load capacity, lifting height, and portability. Load capacity refers to the maximum weight that the hoist can safely lift; exceeding this limit can be dangerous. The lifting height determines how high the hoist can raise an object, which is essential for tasks that require significant elevation. Additionally, if mobility is a requirement, look for hoists with wheels or other features that facilitate movement. By understanding these basic functionalities, users can make informed decisions that align with their specific lifting needs, ensuring safety and efficiency in their operations.

When selecting the right hydraulic hoist for your lifting needs, it is essential to first identify your specific requirements. According to industry data, approximately 30% of hoist failures are due to improper selection based on inadequate assessments of lifting capacities and application conditions. Therefore, understanding the weight of the load, the height it needs to be lifted, and the environment in which the hoist will operate is crucial. For instance, if you need to lift heavy machinery in an indoor facility, the specifications might differ significantly from lifting equipment outdoors under various weather conditions.

Additionally, assessing factors such as the frequency of use and the required lifting speed will impact your choice. Reports indicate that the average workload of hydraulic hoists can vary dramatically, with capacities ranging from 2 tons to over 20 tons depending on the design and intended use. In environments where hoists are operated frequently, choosing a model with a higher duty cycle can enhance efficiency and reduce wear and tear. Therefore, thorough planning and understanding of your unique lifting tasks will help ensure that you select a hydraulic hoist that meets both current and future demands effectively.

When evaluating different types of hydraulic hoists available in the market, the first consideration is the capacity of the hoist. Hydraulic hoists come in various lifting capacities, often ranging from a few tons to several dozen. It’s crucial to select a hoist that not only meets your current lifting needs but also considers potential future applications. Overloading a hoist can lead to equipment failure and pose safety risks, so understanding your specific lifting requirements is essential.

Another important factor to consider is the design and portability of the hydraulic hoist. Some models are fixed installations suitable for permanent setups, while others are more mobile, allowing for use in various locations. If the hoist will frequently be moved or used in different environments, look for features such as wheels or a lightweight design. Additionally, examine the hoist's operating height and reach; this will help ensure that it can safely lift items to the required height without compromising stability or safety.

Finally, consider the control mechanisms of the hydraulic hoist. Different hoists utilize various controls, from manual levers to electrical buttons. Assessing the ease of use and safety features of the control system is vital for ensuring smooth operation, especially in high-demand environments. By taking these factors into account, you can make an informed decision about which hydraulic hoist best suits your lifting needs.

| Type of Hydraulic Hoist | Load Capacity (tons) | Lift Height (ft) | Power Source | Ideal Use Case |

|---|---|---|---|---|

| Portable Hydraulic Hoist | 1 | 10 | Manual/Pneumatic | Home Projects, Small Garage Work |

| Electric Hydraulic Hoist | 2 | 15 | Electric | Construction Sites, Factories |

| Chain Block Hoist | 3 | 10 | Manual | Heavy Lifting, Warehouse |

| Hydraulic Floor Hoist | 5 | 36 | Electric | Automotive Repairs |

| Telescopic Hydraulic Hoist | 10 | 20 | Diesel/Electric | Construction, Infrastructure |

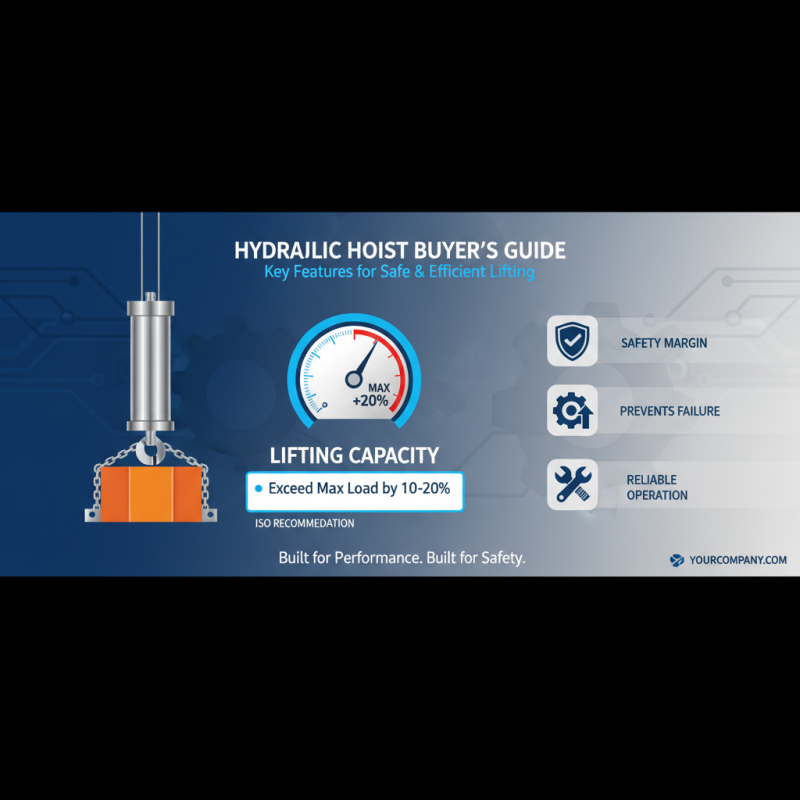

When selecting a hydraulic hoist for your lifting needs, there are several key features you should consider to ensure efficient and safe operations. First and foremost is the hoist's lifting capacity. According to a report from the International Organization for Standardization (ISO), choosing a hoist with a capacity that exceeds your maximum lifting requirements by at least 10-20% is advisable. This safety margin can help prevent equipment failure and accidents.

Another critical feature to look for is the hoist's lifting speed and stroke length. The efficiency of a hoist often correlates with how quickly it can raise and lower loads. Industry benchmarks indicate that a lifting speed of around 10 to 15 feet per minute is typical for many hydraulic hoists, making them suitable for tasks requiring moderate lifting cycles, while slower speeds may be better for more delicate operations. Additionally, the stroke length should be compatible with your workspace; a longer stroke allows for greater versatility but can also add to the hoist’s footprint.

Lastly, consider the construction and durability of the hydraulic hoist. Materials used in the hoist structure can greatly influence longevity and performance under stress. Reports reveal that hoists made from high tensile steel or advanced composite materials can withstand harsher environments and offer more reliable service. Regular maintenance and inspection of hydraulic systems are equally crucial, with up to 20% of hoist failures attributed to inadequate upkeep, highlighting the need for a robust design that facilitates maintenance.

When selecting a hydraulic hoist, safety standards should be a primary consideration. Ensure that the hoist meets relevant local and international safety regulations. Look for certifications that indicate compliance with established safety protocols. These may include load capacity ratings, overload protection mechanisms, and emergency shutoff systems. A hoist that conforms to recognized safety standards minimizes the risk of accidents and enhances overall workplace safety. Regularly reviewing the manufacturer's guidelines and safety documentation is crucial to maintain an awareness of best practices.

Maintenance is equally important in ensuring the long-term functionality and safety of hydraulic hoists. Regular inspections should be conducted to check for signs of wear and tear, such as leaks in hydraulic lines or damage to the lifting mechanism. It is advisable to develop a routine maintenance schedule that includes lubrication of moving parts, checking hydraulic fluid levels, and replacing worn components promptly. Keeping detailed records of maintenance activities can help in identifying patterns of wear over time, thereby preventing potential malfunctions and ensuring that the hoist functions optimally. Regular training for operators on maintenance protocols is also essential to ensure safe and efficient operation.