Inquiry

Form loading...

-

E-mail

-

Whatsapp

Choosing the right Electric Trolley Hoist for your lifting requirements can be a challenging task, given the myriad of options available on the market today. Industry expert John Smith, a well-respected engineer with over 20 years of experience in material handling solutions, emphasizes the importance of understanding your specific needs. He once stated, “Selecting the ideal Electric Trolley Hoist is not just about lifting capacity; it’s about ensuring safety and efficiency in your operations.”

As lifting applications become more complex, the criteria for choosing an Electric Trolley Hoist also evolve. Factors such as load weight, lift height, and operational environment play crucial roles in the selection process. Knowledge of the various types of hoists, their functionalities, and suitable applications is essential for making an informed decision that enhances productivity while minimizing risks.

In this guide, we will explore the fundamental aspects to consider when choosing the best Electric Trolley Hoist tailored to your needs. By examining key features and providing essential insights, we aim to equip you with the knowledge necessary to navigate the selection process effectively, ultimately leading you to the most suitable lifting solution for your specific applications.

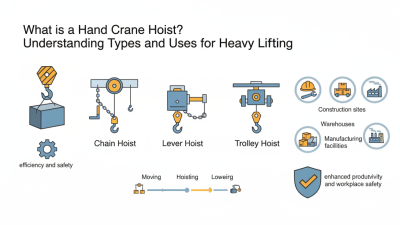

Electric trolley hoists play an essential role in various industrial applications, providing efficient lifting solutions that enhance productivity and safety in the workplace. At their core, electric trolley hoists consist of a motorized lift system that can move along a beam or track, allowing for seamless maneuverability of heavy loads. According to the Material Handling Industry of America (MHIA), the global market for electric hoists is projected to grow significantly, with an expected compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. Understanding the basics of these hoists is crucial for making informed decisions tailored to specific lifting needs.

When selecting an electric trolley hoist, it is vital to assess the weight capacity required for your operations. Most hoists come with varying load limits, typically ranging from 1 ton to 15 tons or more, making it essential to choose a model that can safely handle the maximum weight you will be lifting regularly. Additionally, factors such as lift speed, duty cycle, and power source should be taken into consideration. According to the American Society of Mechanical Engineers (ASME), improper selection of lifting equipment can lead to accidents, which makes adherence to safety standards paramount. Moreover, understanding the hoist's operational environment, including factors such as space constraints and potential hazards, will further guide you to select the most appropriate electric trolley hoist for your specific needs.

When selecting an electric trolley hoist, the first step is to assess your lifting capacity requirements accurately. Understanding how much weight you intend to lift is crucial, as it informs your choice of hoist specifications. Consider the maximum weight you'll need to handle in your operations. This encompasses not just the payload itself but any additional factors such as attachments, rigging equipment, or any other items that might contribute to the overall weight. It's wise to choose a hoist that slightly exceeds your maximum weight requirements to ensure safety and efficiency during lifting tasks.

Additionally, think about the lifting height needed for your specific applications. Different jobs may require varying lift heights, which can influence the design and functionality of the hoist. Some tasks may necessitate lifting materials to significant heights, while others might require only moderate elevation. Evaluate the operational space available and any overhead constraints, as these will affect the type and model of hoist suitable for your setting. By thoroughly considering both lifting capacity and height requirements, you can select the right electric trolley hoist that fulfills your needs safely and effectively.

| Hoist Model | Lifting Capacity (lbs) | Lift Height (ft) | Power Source | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 1000 | 20 | Electric | 150 | 250 |

| Model B | 2000 | 15 | Electric | 180 | 450 |

| Model C | 1500 | 10 | Electric | 160 | 350 |

| Model D | 2500 | 25 | Electric | 200 | 600 |

When selecting an electric trolley hoist, it is crucial to consider several key features that directly impact performance and safety. One of the foremost factors is the hoist's lifting capacity, which typically ranges from 0.5 tons to over 100 tons. Industry reports indicate that the demand for compact hoists with higher capacities is increasing, especially in sectors such as construction and manufacturing where efficiency and power are paramount. It is essential to choose a hoist that not only meets your lifting requirements but also has a margin for safety to handle unexpected overloads.

Another vital feature to evaluate is the hoist's speed and lifting height. Many modern electric hoists offer variable speed settings, allowing users to adjust the lifting speed according to the task at hand. For example, a report from the Material Handling Industry (MHI) highlights that faster hoists can improve overall productivity by up to 30%. Additionally, assessing the lifting height required for your operations is crucial, as some models may only accommodate shorter lifts, which may not suffice for taller warehouses or construction sites.

Lastly, safety features should be a top priority when choosing an electric trolley hoist. Key safety elements include overload protection, emergency stop functions, and limit switches, which ensure that the hoist operates within safe parameters. According to the Occupational Safety and Health Administration (OSHA), nearly 50% of workplace injuries involving lifting equipment are attributable to equipment failure or improper use. Therefore, selecting a hoist equipped with robust safety mechanisms can significantly mitigate risks and enhance operational reliability.

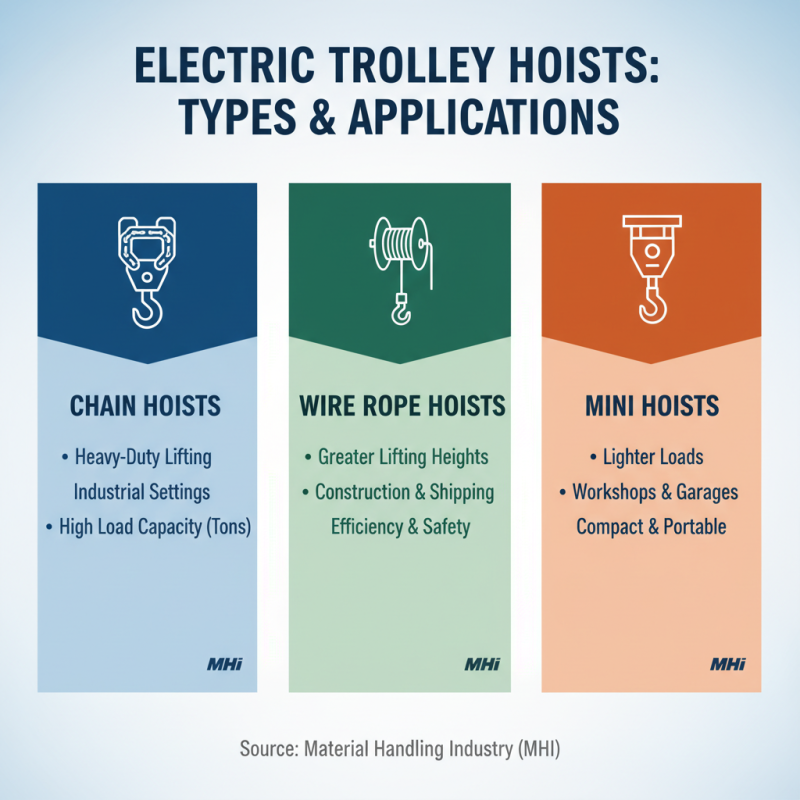

When it comes to selecting the best electric trolley hoist for your lifting requirements, it is essential to understand the distinctions among various types available in the market. Electric trolley hoists can typically be categorized into three primary types: chain hoists, wire rope hoists, and mini hoists. Each of these categories serves different applications and has unique advantages. According to the Material Handling Industry (MHI), chain hoists are ideal for heavy-duty lifting and are commonly used in industrial settings, offering load capacities that can exceed several tons. In contrast, wire rope hoists provide greater lifting heights and are often utilized in construction and shipping operations, as they combine efficiency with safety features.

Moreover, mini hoists have gained popularity in recent years, particularly within the DIY and small business sectors. These compact models usually have a maximum load capacity of around 500 kg, making them suitable for lighter tasks. Data from the Global Hoisting Equipment Market Report indicates that the demand for mini hoists is projected to grow significantly, reflecting the increase in home improvement projects and small-scale industrial applications. By analyzing your specific lifting needs—considering factors such as load capacity, lifting height, and intended environment—you can effectively select the appropriate electric trolley hoist type that aligns with your operational goals.

When selecting an electric trolley hoist, safety should be a paramount consideration. First and foremost, ensure that the hoist you choose meets the necessary safety standards and regulations for your specific application. Look for features like overload protection, which prevents the hoist from lifting more than its rated capacity, and emergency stop buttons that can quickly halt operation in case of an emergency. Additionally, consider the hoist's design, ensuring that it provides stability and minimizes the risk of tipping.

Tips: Before making a purchase, conduct a thorough risk assessment of your lifting environment. Identify potential hazards such as overhead obstructions, uneven surfaces, and electrical safety issues. This will help you choose a hoist with the right specifications for your specific conditions.

Another critical factor in safety is the operator's training. Ensure that anyone who will be using the hoist is properly trained in its operation and understands the safety protocols that must be followed. Regular maintenance and inspection of the hoist are also essential to ensure it operates safely and efficiently. A well-maintained hoist can significantly reduce the risk of accidents and prolong the lifespan of your equipment.