Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the ever-evolving landscape of industrial operations, the choice of the right equipment can significantly impact efficiency and productivity. Among the myriad solutions available, the "Industrial Hydraulic Lift" stands out as a crucial piece of machinery for businesses seeking to enhance their material handling capabilities. According to a recent report by the Industrial Equipment Manufacturers Association, the demand for hydraulic lifts is projected to grow by over 5% annually, reflecting their essential role in modern industrial settings.

Expert in the field, Dr. Henry Covington, a leading authority on industrial machinery, emphasizes the importance of proper selection, stating, "Choosing the right Industrial Hydraulic Lift is not just about capacity; it's about understanding the unique needs of your business operation." He highlights that factors such as load requirements, workplace dimensions, and safety regulations should all be carefully considered to optimize the lift’s utility. With an informed approach to selection, businesses can ensure they are not only meeting their current operational needs but also preparing for future growth and challenges in a competitive market.

Industrial hydraulic lifts are essential tools in various industries, designed to efficiently raise and lower heavy loads. Understanding the different types of hydraulic lifts available is crucial for businesses aiming to optimize their operations. Common types include scissor lifts, boom lifts, and platform lifts, each serving specific functionalities. Scissor lifts are ideal for providing stable elevation for tasks that require access to heights, making them suitable for warehouses or construction sites. Boom lifts, on the other hand, are perfect for reaching over obstacles, offering flexibility for maintenance and installation jobs.

When choosing the right hydraulic lift, it's important to consider the specifications that align with your business needs. Key specifications include the lifting capacity, platform size, and maximum lift height. Lifting capacity dictates how much weight the lift can safely handle, while platform size impacts the amount of equipment or personnel that can be accommodated during tasks. Additionally, the maximum lift height will determine the reach available for various applications. Businesses should also evaluate portability features, power source options, and safety mechanisms, ensuring the lift not only meets operational demands but also adheres to safety regulations in the workplace.

| Type of Lift | Load Capacity (lbs) | Lift Height (ft) | Power Source | Best Use Case |

|---|---|---|---|---|

| Scissor Lift | 3,000 | 20 | Electric | Warehouse Stacking |

| Boom Lift | 1,500 | 40 | Diesel | Outdoor Maintenance |

| Forklift | 5,000 | 10 | Gas/Diesel | Material Handling |

| Vertical Mast Lift | 500 | 30 | Electric | Indoor Use |

| Platform Lift | 1,000 | 5 | Electric | Loading Docks |

When selecting the appropriate industrial hydraulic lift for your business, one of the most critical factors to consider is load capacity. Assessing this metric accurately can significantly impact operational efficiency and safety. According to a report by the Industrial Truck Association, a majority of workplace injuries linked to material handling originate from improperly loaded lifts, highlighting the importance of adhering to manufacturers' specifications. For example, choosing a lift with a load capacity that matches or exceeds the maximum expected weight is vital; overstressing a lift not only endangers personnel but can also lead to costly equipment failures.

An effective evaluation of load capacities should involve analyzing not only the maximum weight a lift can handle but also factors such as the distribution of that weight and the frequency of use. A study revealed that companies that calculated their average loads often benefitted from lifts with a 20% higher capacity than their peak demands. This buffer allows for operational flexibility, reducing strain and extending the lifespan of the equipment. Additionally, understanding the types of materials being moved, whether they are evenly distributed or concentrated, plays a crucial role in selecting an appropriate lift. By following these guidelines, businesses can ensure that their hydraulic lift solutions align seamlessly with their operational needs while maintaining workplace safety.

This chart illustrates various load capacities that industrial hydraulic lifts can handle, helping businesses assess their options based on their specific needs.

When selecting an industrial hydraulic lift, space considerations are paramount. The dimensions of the lift and the layout of the workspace not only dictate functionality but also impact safety and efficiency. According to industry reports, approximately 30% of operational downtime in warehouses is attributed to poor space utilization and misalignment of equipment. Therefore, analyzing available floor space and ensuring that the lift’s footprint complements existing infrastructure is crucial.

To effectively evaluate space, businesses should first measure the height, width, and load capacities required for their operations. Industry standards recommend that the working height of a lift should exceed the maximum elevation needed for tasks by at least 20% to ensure safe maneuverability. In addition, the layout must accommodate the lift's access points without obstructing critical pathways or emergency exits, as reported by the Occupational Safety and Health Administration (OSHA). Such strategic planning ensures not only that the hydraulic lift meets operational needs but also enhances overall workflow efficiency, thereby minimizing unnecessary delays and potential hazards.

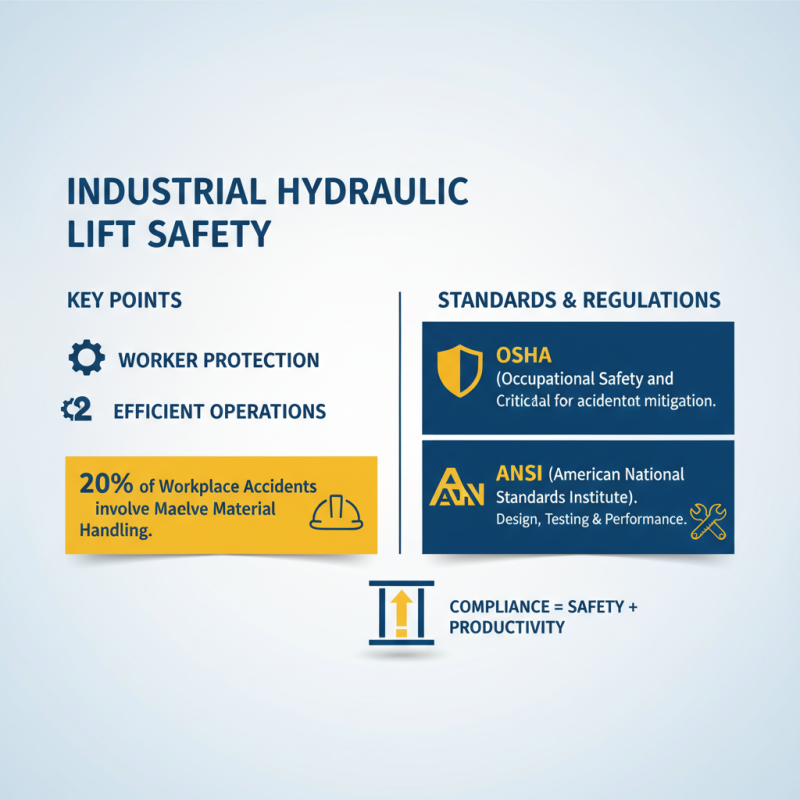

When selecting an industrial hydraulic lift, compliance with safety standards and regulations is paramount to ensuring both the protection of workers and the efficient operation of business processes. According to the Occupational Safety and Health Administration (OSHA), approximately 20% of workplace accidents involve material handling, making adherence to safety guidelines critical. The American National Standards Institute (ANSI) outlines specific requirements for the design, testing, and performance of hydraulic lifts, which help mitigate risks associated with equipment failure and operator error.

Moreover, compliance with these safety standards is not only a legal obligation but also a crucial factor in maintaining operational efficiency. A recent report by the National Safety Council indicated that businesses that prioritize safety compliance experience up to a 30% reduction in workplace accidents. This can lead to lower insurance premiums, increased productivity, and improved employee morale. Choosing the right hydraulic lift means not only evaluating the equipment's capabilities but also ensuring that it meets stringent safety regulations, which ultimately protects both the workforce and the bottom line.

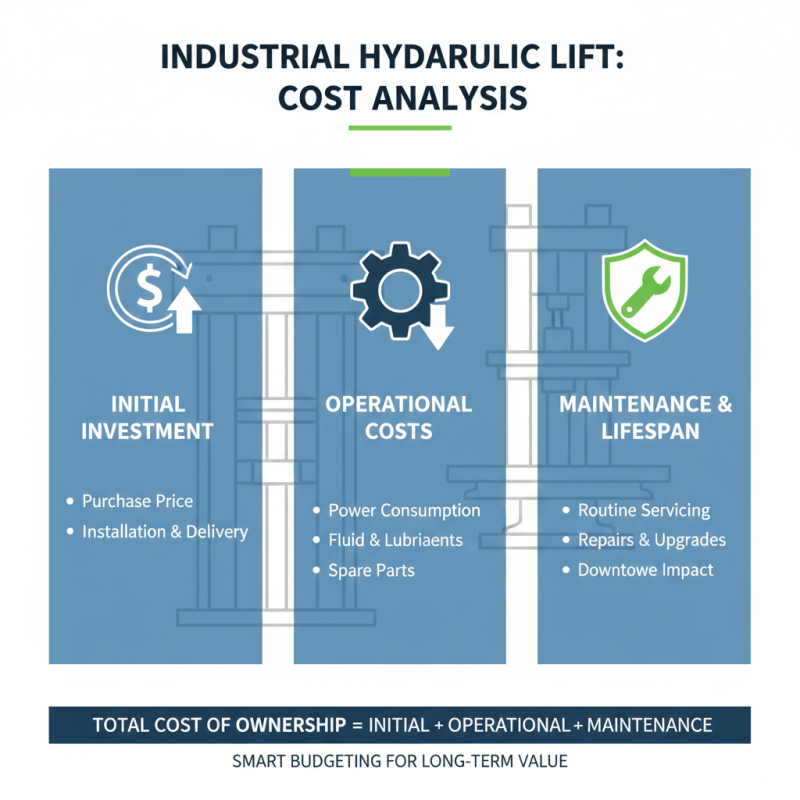

When considering the acquisition of an industrial hydraulic lift, cost analysis is a fundamental aspect to ensure your investment aligns with your business needs. The total cost of ownership includes not only the purchase price but also ongoing maintenance and operational expenses. It's essential to budget for both initial expenditures and long-term costs to avoid unexpected financial burdens down the line.

Tips for budgeting effectively include conducting a thorough research phase to understand the variety of hydraulic lifts available, as prices can vary significantly based on features and capabilities. Additionally, factor in the costs of regular maintenance and potential repairs. Setting aside a percentage of your budget for these unforeseen expenses can help ensure that your lift remains operational without straining your financial resources. It might also be beneficial to compare the potential return on investment by considering how the lift will improve operational efficiency and productivity in your business.

Moreover, look into warranties and service packages offered by suppliers, as these can save you money on repairs and maintenance over time. Prioritizing quality now can lead to reduced operational costs in the future, making the right financial choices integral to your overall success. By carefully analyzing all these aspects, you can make a wise investment in a hydraulic lift that propels your business forward.