Inquiry

Form loading...

-

E-mail

-

Whatsapp

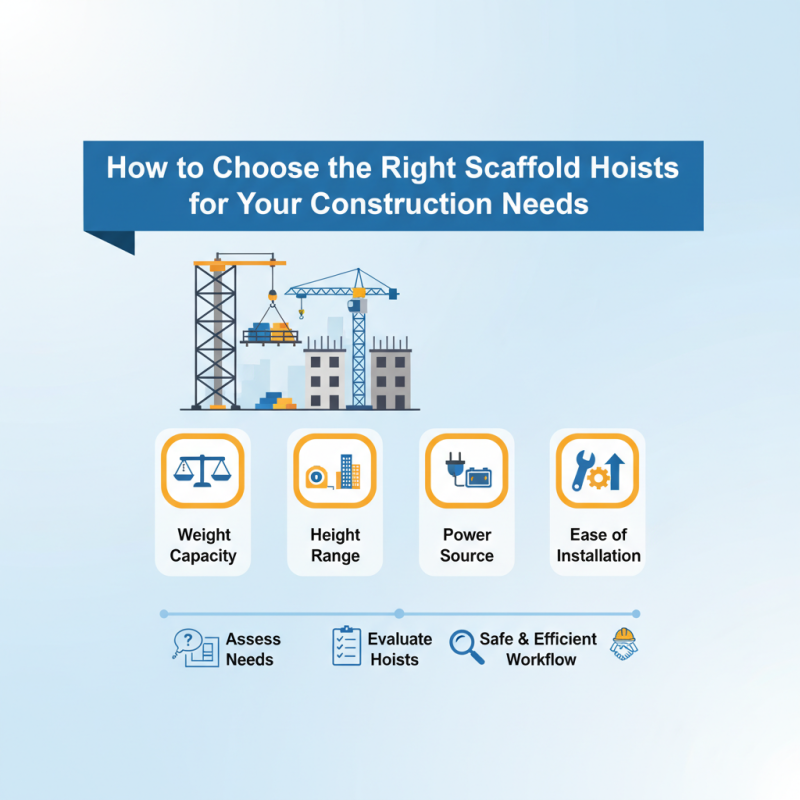

When it comes to construction projects, the importance of choosing the right equipment cannot be overstated. Among the various tools and equipment essential for efficient construction operations, Scaffold Hoists stand out as crucial components that enhance productivity and safety on job sites. These hoists are specifically designed to facilitate the vertical movement of materials and personnel, making them indispensable for tasks that involve working at heights. However, selecting the most suitable Scaffold Hoists for your specific needs requires careful consideration of several factors.

In this guide, we will explore the key elements to consider when choosing Scaffold Hoists, ensuring that your construction projects can be executed smoothly and safely. Factors such as weight capacity, height range, power source, and ease of installation will be discussed in detail, allowing you to make an informed decision. With the right Scaffold Hoists, you can significantly expedite work processes while minimizing risks associated with manual handling and height access. Understanding your unique construction needs and the characteristics of available hoists is essential for achieving a successful and efficient workflow on any job site.

When choosing scaffold hoists for construction projects, understanding the various types and their features is crucial. Scaffold hoists can generally be classified into several categories based on their mechanism and intended use. For instance, electric hoists provide reliable lifting capabilities, suitable for both heavy and lightweight materials, with lifting capacities often ranging from 500 to 2,000 pounds. According to the Occupational Safety and Health Administration (OSHA), proper selection of a hoist type can significantly improve safety and efficiency on construction sites.

In addition to type, key features such as load capacity, height, and control systems must also be considered. Many hoists are equipped with limit switches that prevent overloading, while others may feature programmable controls for precise lifting. Reports from the Construction Equipment Association indicate that hoists with advanced safety features and user-friendly controls can enhance productivity by up to 30%. Evaluating these specifications allows contractors to select the right scaffold hoist that not only meets safety standards but also optimizes work site operations. Lastly, portability and ease of setup can further influence the decision, as these factors directly impact project timelines and costs.

| Type of Scaffold Hoist | Load Capacity (kg) | Lift Speed (m/min) | Power Source | Ideal Use Case |

|---|---|---|---|---|

| Electric Scaffold Hoist | 500 | 20 | Electric | Heavy-duty construction |

| Manual Scaffold Hoist | 300 | N/A | Manual | Light-duty work |

| Pneumatic Scaffold Hoist | 400 | 15 | Compressed Air | Medium-duty applications |

| Gear Rack Hoist | 600 | 10 | Electric | Construction sites with high lifts |

| Self-erecting Hoist | 800 | 25 | Electric | High-rise buildings |

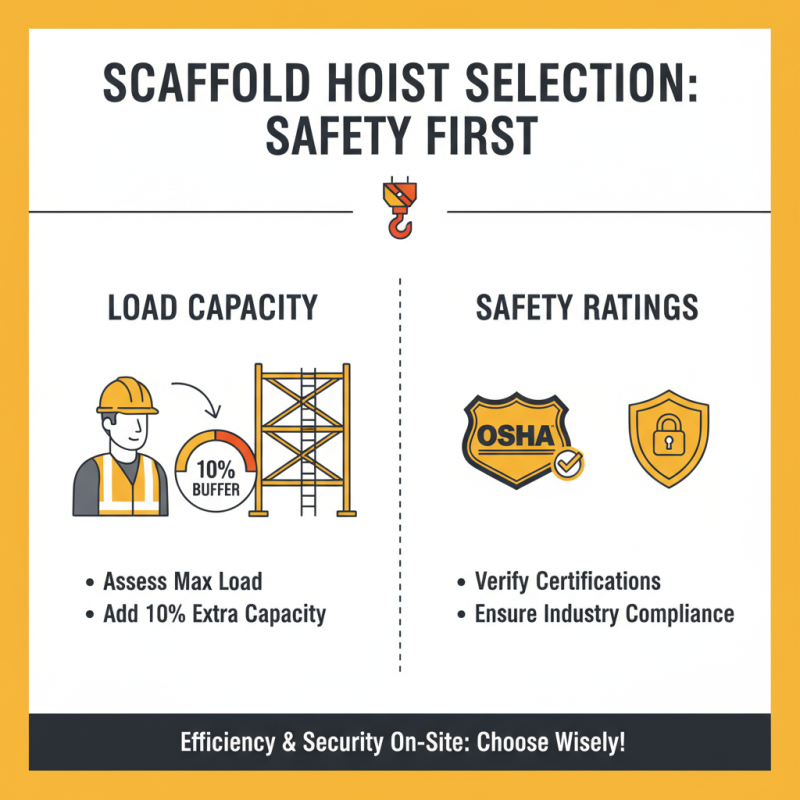

When selecting scaffold hoists for construction projects, properly assessing load capacity and safety ratings is essential to ensure both efficiency and security on the job site. According to industry standards outlined by organizations like the Occupational Safety and Health Administration (OSHA), it's crucial to choose hoists that can handle at least 10% more than the maximum expected load. For instance, if the anticipated load is 1,000 pounds, a hoist with a minimum capacity of 1,100 pounds is recommended. This extra margin helps accommodate unexpected weight increases and provides a buffer against wear over time.

In addition to load capacity, understanding safety ratings is vital. Many hoists come equipped with features such as overload protection, emergency brakes, and safety locks, which enhance operational safety. The American National Standards Institute (ANSI) offers guidelines on these specifications, which should be carefully considered when evaluating options. Always look for hoists that meet or exceed these standards, as they have been tested for safety and reliability in real-world conditions.

Tips: When comparing different hoists, consider conducting a risk assessment on your job site to better understand the required specifications. Additionally, consult with safety professionals or industry experts who can provide insights into the latest safety developments and regulations. This proactive approach can greatly reduce the risk of accidents and improve the overall operational efficiency of your construction project.

When selecting scaffold hoists for construction projects, one of the most crucial factors to consider is the power source. Electric hoists offer several advantages, particularly in terms of efficiency and user-friendliness. They are typically faster and require less physical effort from operators, which can enhance productivity on site. Electric models are often equipped with advanced features such as variable speed control and automatic shut-off systems, providing greater safety and control during lifting operations.

On the other hand, manual hoists, while requiring more physical labor, can be more cost-effective for smaller projects or when power access is limited. They are lightweight and portable, making them easy to transport and set up in various locations. Additionally, manual hoists can be ideal for workers who prefer hands-on operation or for jobs where electricity has safety concerns.

Tips: When considering electric hoists, assess the power supply availability at your site and ensure proper training for operators on the equipment's electrical components. For manual hoists, ensure that your team is physically prepared for the physical demands of operation and that all safety protocols are in place. Always balance between efficiency and labor requirements to find the best fit for your construction needs.

When selecting scaffold hoists for construction projects, considering durability and weather resistance is essential to ensure long-term reliability. Hoists are often exposed to harsh elements, including rain, wind, and extreme temperatures. Therefore, materials used in construction, such as high-grade steel or aluminum, offer enhanced resistance to corrosion and degradation. Make sure to choose hoists that come with protective coatings or finishes specifically designed to withstand the rigors of outdoor use.

Tips: Always inspect the hoist for any signs of wear and tear before use, especially after exposure to inclement weather. Regular maintenance, such as cleaning and lubricating moving parts, can significantly extend the lifespan of your hoisting equipment.

Moreover, the design of the hoist plays a crucial role in its ability to resist weather impacts. Look for models with seals or tight fittings to prevent moisture ingress and secure electrical components from humidity. Additionally, choosing hoists that feature modular designs can facilitate easier maintenance and upgrades, further enhancing their durability over time.

Tips: Consider the geographical location of your construction site when selecting hoists. Areas prone to high humidity or extreme weather may necessitate hoists with enhanced specifications for weather resistance.

When it comes to budgeting for scaffold hoists, it's crucial to understand the significant financial investment they represent in any construction project. According to a recent industry report by the National Institute of Standards and Technology (NIST), scaffolding-related costs can account for nearly 20% of overall construction expenses. This emphasizes the need for careful consideration and planning when selecting the right scaffold hoists to fit specific project requirements.

A typical scaffold hoist can range from $1,000 to over $5,000 depending on the specifications, lifting capacity, and operational features. It's essential to assess the appropriate load capacity since underestimating needs may lead to disruptions and additional costs down the line. Additionally, maintenance and operational training should be factored into the budget, as neglecting these can escalate long-term costs. The construction industry should also consider the economic impact of downtime. Research indicates that every hour of delay on site can cost upwards of $300 to $1,000, thereby making the selection of efficient, reliable hoists a crucial component of budgetary analysis and effective project management.