Inquiry

Form loading...

-

E-mail

-

Whatsapp

When it comes to selecting the right Trolley Crane Hoist for your operational requirements, the decision-making process can often feel daunting. Industry expert, John Anderson, a renowned material handling specialist, emphasizes the importance of making an informed choice: "Choosing the appropriate Trolley Crane Hoist not only enhances efficiency but also significantly impacts safety and productivity in the workplace." His insights highlight that understanding the unique needs of your project is vital in this intricate process.

The Trolley Crane Hoist, with its versatility and strength, has become an indispensable tool in various industries, from construction to manufacturing. It is crucial to assess your specific lifting capacities, the type of materials being moved, and the operational environment. By carefully evaluating these factors, you can determine the hoist that will suit your needs best, thereby optimizing your workflow and minimizing risks.

Moreover, considering features such as ease of installation and maintenance, as well as the safety mechanisms integrated into the design, can further guide your decision. With an array of options available in the market, being well-informed about the capabilities and limitations of different Trolley Crane Hoists will empower you to make a choice that aligns perfectly with your operational goals.

When selecting a trolley crane hoist, understanding its key features and types is essential for ensuring that it meets your operational needs. Trolley crane hoists are classified primarily into two types:

manual hoists and

electric hoists. Manual hoists are often compact and lightweight, making them ideal for smaller operations or environments where power availability is limited. In contrast, electric hoists offer greater lifting capacities and faster operation speeds, making them preferable for large industrial applications.

According to the Crane Manufacturers Association of America, electric hoists can handle loads up to 100 tons or more, significantly increasing productivity in heavy-load scenarios.

According to the Crane Manufacturers Association of America, electric hoists can handle loads up to 100 tons or more, significantly increasing productivity in heavy-load scenarios.

When considering specifications, pay attention to the lift height, speed, and load capacity. For example, a hoist designed for heavy-duty use should include features like overload protection and advanced control systems for safety and precision. The range of lifting speeds generally varies from 10 to 40 feet per minute, depending on the hoist's intended application. Reports from the Material Handling Industry show that organizations that strategically select hoisting equipment based on these features experience a 30% reduction in downtime due to equipment failure.

Tips: Always assess your maximum load requirements before making a purchase and consider future growth that may require higher capacity. Additionally, consulting with industry professionals can provide valuable insights into the latest technological advancements in hoists, ensuring you select a trolley crane hoist that not only meets your current needs but also adapts to future demands.

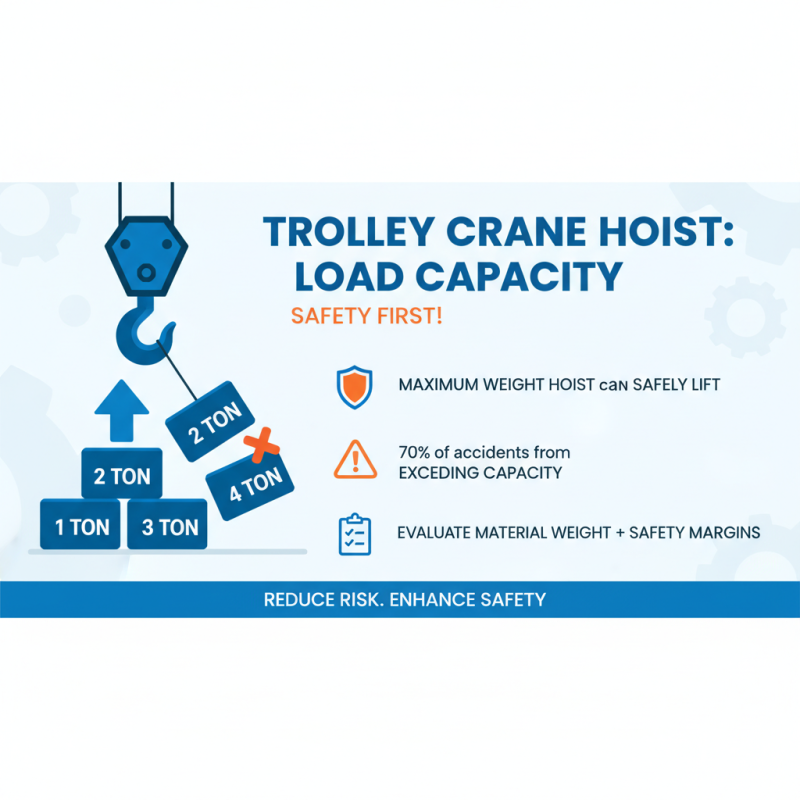

When choosing the right trolley crane hoist, one of the most critical factors to consider is your load capacity requirements. The load capacity refers to the maximum weight that the hoist can safely lift and is usually expressed in tons. According to a report from the Material Handling Industry of America (MHIA), nearly 70% of hoist-related accidents stem from exceeding the designated load capacity. It is essential to accurately evaluate the weight of the materials you plan to handle, including any additional safety margins. This ensures that the hoist operates within safe limits, thereby reducing the risk of equipment failure and enhancing workplace safety.

In assessing load capacity, consider not only the static weight but also dynamic factors such as shock loads or load sway during transport. The International Organization for Standardization (ISO) suggests using a load capacity that exceeds the expected maximum weight by at least 20%. This recommendation accounts for unforeseen operational stresses. Additionally, if you plan to lift heavier or bulkier items, you might want to invest in a hoist with a higher capacity than you believe you will need. Investing in a hoist with ample load capacity can ultimately save costs in the long run, as it allows for greater versatility and adaptability in your lifting operations.

When evaluating power sources for trolley crane hoists, the choice between electric and manual hoists is critical and should be guided by specific operational needs.

Electric hoists are powered by electricity and tend to be more efficient and faster in lifting and lowering loads. According to the Association of Equipment Manufacturers (AEM), electric hoists can typically lift loads up to 80% faster than their manual counterparts, significantly improving productivity in busy work environments. Furthermore, electric hoists require less physical effort from operators, which can reduce the risk of workplace injuries associated with repetitive strain.

On the other hand, manual hoists offer several advantages in scenarios where electrical power may not be available, such as outdoor or remote job sites. They are often lighter and more portable, making them easier to set up quickly.

The Occupational Safety and Health Administration (OSHA) notes that manual hoists can be a more budget-friendly option for companies not needing extensive lifting capabilities or frequent use. Additionally, they often require less maintenance, which can be a cost-saving consideration for smaller businesses or those with limited budgets. Ultimately, the decision between electric and manual hoists should align with the specific demands of the job and the operational environment.

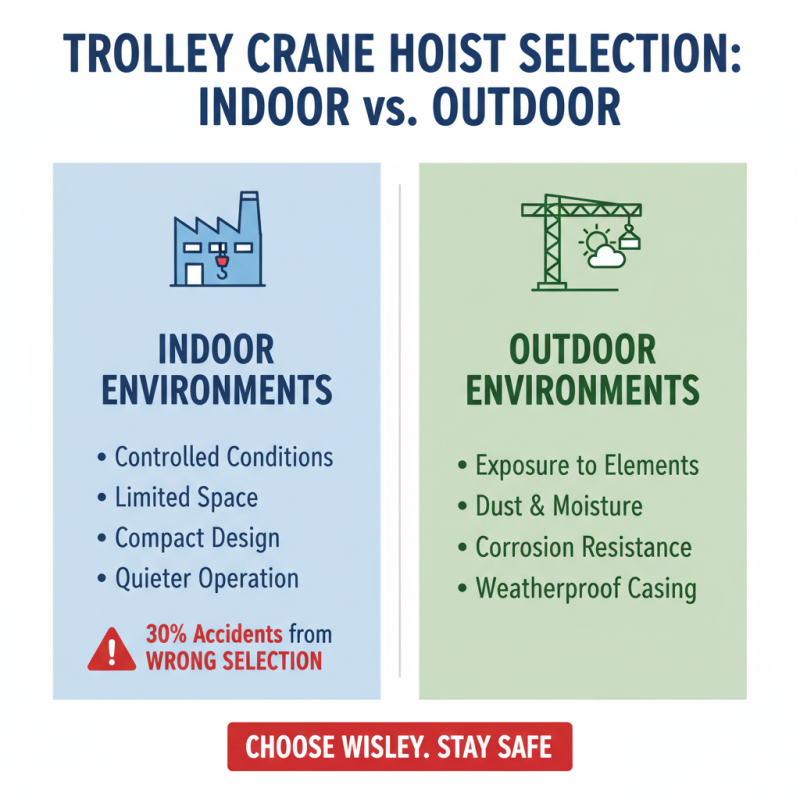

When selecting the right trolley crane hoist, understanding the environment in which it will be used is crucial, particularly when distinguishing between indoor and outdoor applications. According to industry reports, approximately 30% of hoist-related accidents occur due to improper equipment selection for the operational environment. Indoor environments typically feature controlled conditions with limited space, necessitating a hoist that operates efficiently within such constraints. Features like compact design and quieter operation are particularly advantageous in warehouses or manufacturing facilities where noise limitations are often in place.

In contrast, outdoor applications must contend with a variety of environmental factors such as wind, rain, and extreme temperatures. For instance, studies from the Crane Manufacturers Association of America indicate that outdoor hoists need to be weatherproofed and designed to withstand harsher conditions, with higher ratings for durability and resistance to corrosion. Additionally, outdoor trolley cranes may require more robust safety features like emergency brakes and enhanced load capacity to accommodate the unpredictable nature of outdoor settings, ensuring reliable performance and safety during operation. Understanding these distinctions helps in making informed decisions that prioritize efficiency and safety for specific usage scenarios.

When selecting a trolley crane hoist, budgeting and maintenance should be pivotal to your decision-making process. The initial cost of the hoist is just one aspect; consider long-term expenses such as maintenance, which can significantly impact your overall investment. Opting for durable yet affordable models can pay off in reduced repairs and longer lifespans. It’s essential to understand what features you need versus what you want, merging functionality with cost-effectiveness.

Tips: Check if the machine is designed for easy maintenance. Models with accessible parts can save you time and labor costs in the long run. Additionally, consider warranty packages, as they can cushion you against unexpected repair expenses. Regular maintenance schedules—backed by the manufacturer’s recommendations—can help avoid costly breakdowns and ensure your hoist operates at peak efficiency.

Investing in high-quality materials and components may lead to a higher upfront cost, but they often reduce the frequency of replacements and repairs over time. When budgeting, assess the total cost of ownership, which includes not just the purchase price but also energy consumption and the cost of potential downtime. Making informed decisions at this stage can help you find a trolley crane hoist that meets your needs while remaining financially sustainable.