Inquiry

Form loading...

-

E-mail

-

Whatsapp

Choosing the right scaffold hoists for your project is crucial. These tools enhance efficiency and safety. With various options available, selecting the best option can be daunting.

Scaffold hoists come in different types and capacities. Each project has unique requirements. Consider the weight you will lift. Assess the height and reach needed. Safety features should never be overlooked. It’s vital to prioritize stability and reliability over cost.

Your choice can impact productivity and worker safety. Do thorough research before making a purchase. Read reviews and seek expert opinions. Reflect on your needs and constraints. A wise decision today can lead to smoother operations tomorrow.

When selecting scaffold hoists, understanding their types and features is essential. There are mainly two categories: electric and manual hoists. Electric hoists provide efficiency and speed, making them suitable for large projects. In contrast, manual hoists are more cost-effective and ideal for smaller tasks. According to the latest industry report, approximately 70% of construction sites prefer electric hoists for their ability to handle heavy loads quickly.

Different hoist models come with distinct application features. Some are designed for vertical lifts, while others cater to horizontal needs. Load capacity can vary widely. Most electric hoists support between 500 to 2,000 pounds. It's crucial to choose a model that matches the specific demands of your project. However, not all hoists are easy to operate. Some require additional training. Ensure you understand the training requirements before making any decisions.

Tips: Always check the load capacity. It’s vital to avoid exceeding limits. Also, consider portability for easier maneuvering on site. A hoist might be perfect for one location but impractical for another. Reflect on your project’s unique needs to find the best fit. Don't forget about safety features; they are just as important as load capacity.

| Hoist Type | Key Features | Load Capacity | Application |

|---|---|---|---|

| Electric Hoist | Easy to operate, efficient, suitable for large loads | 500 kg | Construction, industrial lifting |

| Manual Hoist | Cost-effective, requires physical effort | 300 kg | Less demanding lifting tasks |

| Pneumatic Hoist | Fast, suitable for hazardous environments | 400 kg | Automotive, manufacturing |

| Rack and Pinion Hoist | Highly precise, controlled lifting | 800 kg | High-rise construction work |

| Chain Hoist | Durable, reliable overload protection | 1000 kg | Heavy-duty lifting tasks |

When selecting scaffold hoists, evaluating load capacity is crucial. This step ensures safety and efficiency on your construction site. Start by assessing the maximum weight your project will require. Consider not just the materials but also the tools and additional loads. A miscalculation here can lead to dangerous situations.

Tips: Always add a buffer to your estimated load. It’s wise to allow for unexpected weight. This practice can prevent last-minute adjustments that may disrupt your workflow.

Next, think about the type of materials you're using. Heavy items like steel beams or pallets will require more robust hoists. On the flip side, working with lighter materials may not need as much capacity. Reflect on this dynamic as it significantly affects the hoist choice.

Tips: Consult with your team about load demands. Different views might uncover overlooked aspects. A collective evaluation can lead to a more informed decision.

When selecting scaffold hoists, safety standards and compliance are crucial. These regulations ensure that hoists can support heavy loads without risks. Familiarize yourself with local safety codes. This knowledge is vital for making informed choices.

Tips: Always check for certifications. Look for compliance markings on hoists. If you’re unsure, consult safety experts. Knowing the specifications helps avoid accidents.

Regular inspections are essential. Inspect your scaffold hoists before and after each use. Look for wear and damage. If something seems off, do not take risks. Document any issues for future reference. Having a system in place can enhance safety.

Tips: Keep a checklist for inspections. Note down any maintenance issues. This will help in making decisions later on. A small oversight can lead to significant problems. Regular training for workers can also improve compliance and safety awareness.

When selecting scaffold hoists, evaluating power sources is crucial. Electric and manual hoists each come with distinct advantages. Electric hoists can lift heavier loads, often rated for up to 1,000 pounds. This capacity supports larger projects, where efficiency is essential. A study from the Scaffold Industry Association indicates that electric models can reduce labor times by 30-50%. Speed is one reason many contractors prefer electric options.

However, manual hoists should not be overlooked. They are often less expensive and easier to maintain. For smaller projects, a manual hoist may suffice. According to a 2022 market analysis, manual hoists account for around 25% of the scaffold hoist market. This suggests a consistent demand, particularly in residential construction. While they require more physical effort, they can be ideal for tight spaces or projects with limited access to power.

Selecting the right power source depends on job specifics. Consider the weight of materials and site conditions. An electric hoist may seem like a clear choice for larger lifts. Yet, manual hoists are practical in certain scenarios. Each option has its drawbacks, and assessing these carefully is essential for project success.

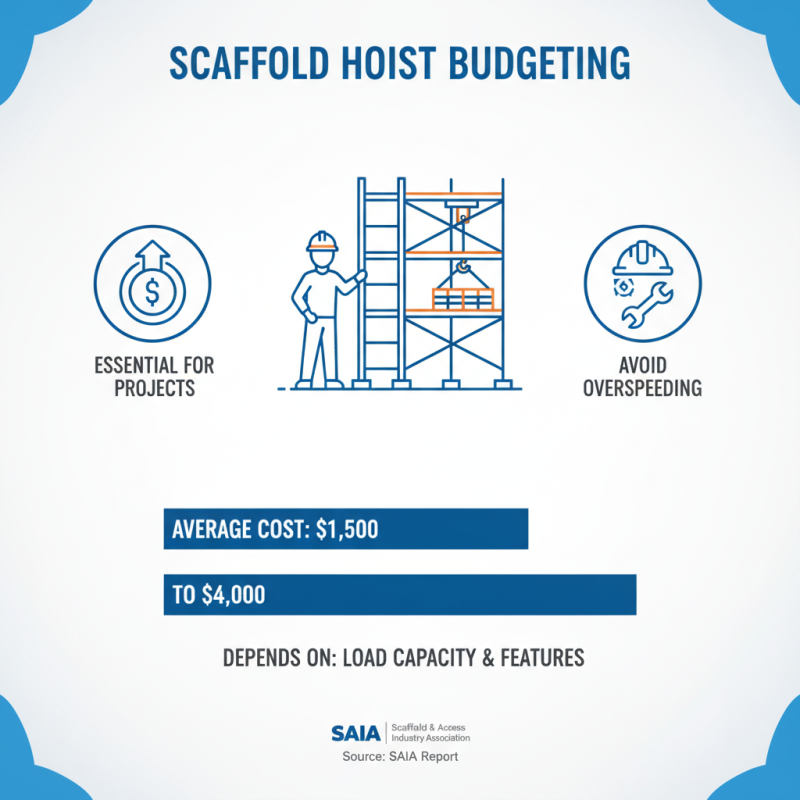

Budgeting for scaffold hoists is essential in any construction project. According to a report by the Scaffold and Access Industry Association (SAIA), the average cost of a scaffold hoist ranges from $1,500 to $4,000. This variation depends on load capacity and technical features. Properly assessing your project's needs can help you avoid overspending.

Consider additional costs when planning your budget. Equipment rental can add up quickly. Daily rental rates can range from $150 to $500, depending on the hoist type and rental duration. Maintenance costs also need attention. Regular upkeep can consume an additional 10-15% of the initial purchase price yearly. Ignoring these factors may lead to unforeseen financial strain.

Additionally, it's crucial to evaluate the project's timeline. Delays can increase costs significantly, especially with equipment rentals. A project that runs longer than expected can double your initial budget for rental fees. Investing time in research and making informed decisions can mitigate these hidden expenses. Reflecting on these financial aspects can lead to a more successful project outcome.