Inquiry

Form loading...

-

E-mail

-

Whatsapp

When it comes to lifting heavy objects safely and efficiently, selecting the right equipment is crucial in various industries from construction to manufacturing. Among the options available, a Hand Crane Hoist stands out as a versatile tool that can make a significant difference in operational productivity. According to the Global Industrial Hoists Market Report, the demand for hoisting equipment is projected to grow at a CAGR of 5.2% over the next five years. This growth highlights the importance of investing in reliable and efficient lifting solutions, particularly for tasks that require precision and safety.

Choosing the best Hand Crane Hoist involves understanding the specific needs of your lifting tasks, as various models come with different capacities, designs, and features. For instance, the American Society of Mechanical Engineers (ASME) emphasizes that selecting the appropriate hoist can significantly impact workplace safety and efficiency, with improper choices leading to accidents or equipment failure. As industries continue to evolve with advanced lifting technologies, being informed about the specifications and advantages of different hand crane hoists is essential for maximizing productivity and minimizing risks in daily operations.

When selecting a hand crane hoist, understanding the various types available in the market is crucial to meeting specific lifting needs effectively. Hand crane hoists typically fall into several categories, including manual chain hoists, lever blocks, and electric hoists. According to a recent report by Research and Markets, the global electric hoist market is expected to grow at a CAGR of 4.7% from 2021 to 2026, reflecting the increasing demand for efficient and easy-to-use lifting solutions.

Manual chain hoists, on the other hand, are known for their simplicity and portability, making them ideal for construction and maintenance tasks. A study by MarketWatch indicates that the manual hoist segment holds approximately 30% of the market share due to its cost-effectiveness and reliability in various industrial settings. Lever blocks are another popular choice, especially in tight spaces, as they require less room to operate. Understanding these types, along with their load capacities and duty cycles, allows users to choose the right hoist that aligns with their lifting requirements and operational preferences.

| Type of Hand Crane Hoist | Load Capacity | Lift Height | Weight | Material | Price Range |

|---|---|---|---|---|---|

| Manual Chain Hoist | 1 ton | 5 m | 8 kg | Steel | $150 - $200 |

| Electric Chain Hoist | 3 tons | 12 m | 30 kg | Aluminum | $600 - $800 |

| Lever Hoist | 2 tons | 3 m | 5 kg | Steel | $100 - $150 |

| Pneumatic Hoist | 1.5 tons | 10 m | 25 kg | Aluminum | $400 - $600 |

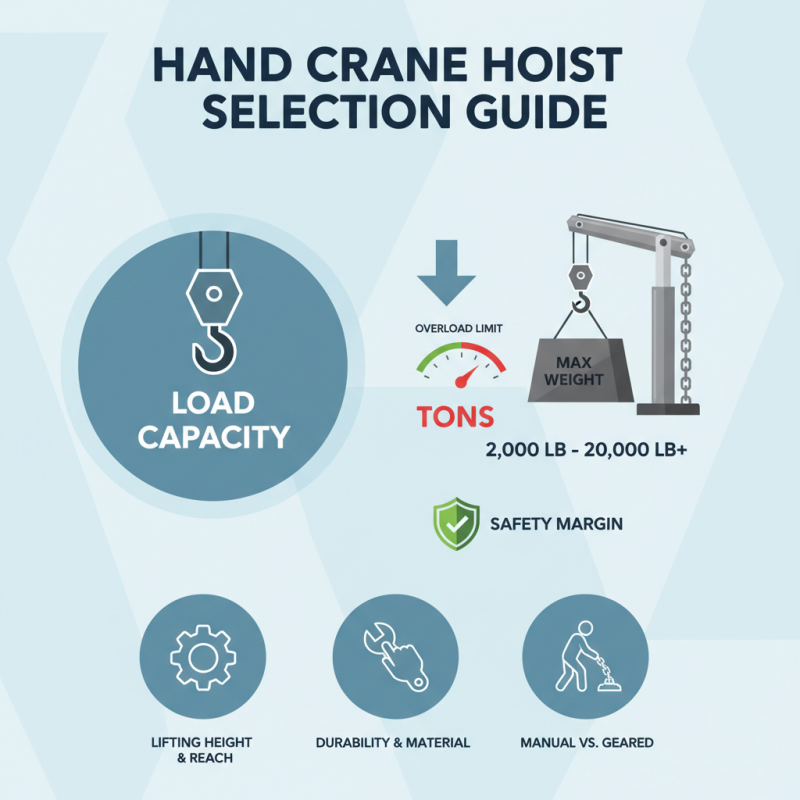

When selecting a hand crane hoist, the first step is to assess your specific lifting requirements, particularly focusing on both weight and height considerations. Understanding the weight of the items you need to lift is crucial; overloading a hoist can lead to equipment failure or safety hazards. Determine the maximum weight you’ll regularly lift and choose a hoist that can handle at least that weight, preferably with some additional margin for safety. This ensures that the hoist will perform effectively, rather than straining the mechanism unnecessarily.

In addition to weight, the height you need to lift is another critical factor. Different tasks require varying lifting heights, so assessing the maximum height your hoist must reach is essential. Ensure that the hoist can provide sufficient lifting height for your needs while maintaining stability and safety throughout the operation. For environments with limited vertical space, opting for a hoist with adjustable height features could be beneficial. By taking the time to analyze these key factors, you can select the hand crane hoist that best meets your specific lifting needs.

When selecting a hand crane hoist, there are several key features to consider to ensure it meets your lifting needs. First, examine the hoist's load capacity. Understanding the maximum weight the hoist can safely lift is crucial to avoid accidents and equipment damage. Always consider the heaviest load you plan to move and choose a hoist with a capacity exceeding that weight to provide an adequate safety margin.

Another important feature is the lifting height. Depending on your workspace, you may require a hoist that can lift items to a certain height. Assess the dimensions of your area and select a hoist with an appropriate lifting range. Additionally, pay attention to the hoist's mechanism, whether it's manual or electric, as this will impact usability and efficiency. Manual hoists may be more portable and require less maintenance, while electric hoists can significantly reduce the physical effort needed for lifting tasks. Overall, focusing on these features will guide you toward making a well-informed choice that enhances your lifting operations.

When selecting a hand crane hoist, it's crucial to consider safety standards and compliance regulations to ensure the equipment's reliability and safety. Compliance with safety standards not only protects workers but also minimizes the risk of accidents during lifting operations. It's important to evaluate the specific safety certifications relevant to hoisting equipment, such as those established by recognized safety organizations.

Tips for choosing a hoist include checking for compliance with local and international safety standards, inspecting the equipment for proper labeling and documentation, and ensuring that the hoist has undergone rigorous testing and evaluation. Additionally, review the manufacturer's reputation and customer feedback to gauge the reliability of the product.

Moreover, understanding the evolving guidelines, such as the recent SQE MARINE circular that launched a campaign for compliance with lifting appliance requirements, can help you stay ahead in maintaining safety in operations. Always prioritize investing in equipment that adheres to the latest safety protocols to ensure the well-being of all personnel involved.

To ensure the longevity and performance of your hand crane hoist, regular maintenance is crucial. According to data from the Material Handling Institute, improper maintenance can reduce a hoist's operational lifespan by up to 50%. Conducting routine inspections can help identify signs of wear and tear, such as frayed cables, misaligned pulleys, or damaged hooks, which, if left unaddressed, can lead to more significant issues and safety hazards.

Lubrication is another critical aspect of maintenance. The Occupational Safety and Health Administration (OSHA) recommends that all moving parts be lubricated regularly to prevent friction and wear. Choosing the right lubricant, compatible with the materials of your hoist, can greatly enhance its efficiency and longevity.

Moreover, keeping your hoist clean, particularly in industrial environments where dust and debris can accumulate, will also contribute to its performance. Following these guidelines will not only extend the life of your hand crane hoist but also ensure safe lifting operations in the long run.