Inquiry

Form loading...

-

E-mail

-

Whatsapp

Choosing the right Power Chain Hoist can be daunting. With numerous options, it's easy to feel overwhelmed. Expert Emma Johnson, a seasoned professional in material handling, states, “The right hoist should match your specific lifting needs.”

When selecting a Power Chain Hoist, consider the load capacity. Evaluate whether the hoist can handle your heaviest items. Take note of the lifting height too. It's crucial that the hoist can reach your required elevation safely.

Additionally, examine the hoist's power source. Electric hoists provide consistent power, while manual options may suit lighter tasks. Finally, reflect on the hoist's durability and maintenance needs. A reliable Power Chain Hoist should be built to last and easy to service. Don't rush this decision – it could impact your operation's efficiency and safety.

Choosing the right power chain hoist involves several key factors to ensure it meets your specific needs. Start by considering the weight capacity. Assess the maximum load you plan to lift. If you underestimate, you may face safety issues. Overloading can damage the hoist or, worse, cause accidents. It’s crucial to get this right.

Next, evaluate the lifting height required for your operations. Measure the distance from the ground to the highest point your load will reach. A hoist with inadequate lifting height may limit your efficiency. Also, think about the required speed of lifting. You want a hoist that can operate at a pace suitable for your workflow. Too slow, and your processes could be delayed; too fast, and you risk losing control.

Durability is another factor. The construction material impacts longevity. Metal hoists withstand heavy use better than plastic options. Check for safety features as well—this adds to the overall reliability of the hoist. Relying on basic models without features can lead to regret later. Reflect on the environment where the hoist will be used. Will it face harsh conditions? This might influence your choice.

| Factor | Description | Importance Level |

|---|---|---|

| Load Capacity | The maximum weight the hoist can lift safely. | High |

| Lift Height | The distance the hoist can lift objects vertically. | Medium |

| Power Source | Electric, manual, or pneumatic options available. | High |

| Speed | How fast the hoist can lift and lower loads. | Medium |

| Durability | Construction quality and longevity of materials used. | High |

| Safety Features | Include overload protection, emergency stop, etc. | High |

| Portability | Weight and design of the hoist for ease of transportation. | Medium |

| Cost | The overall price, balancing budget with features required. | High |

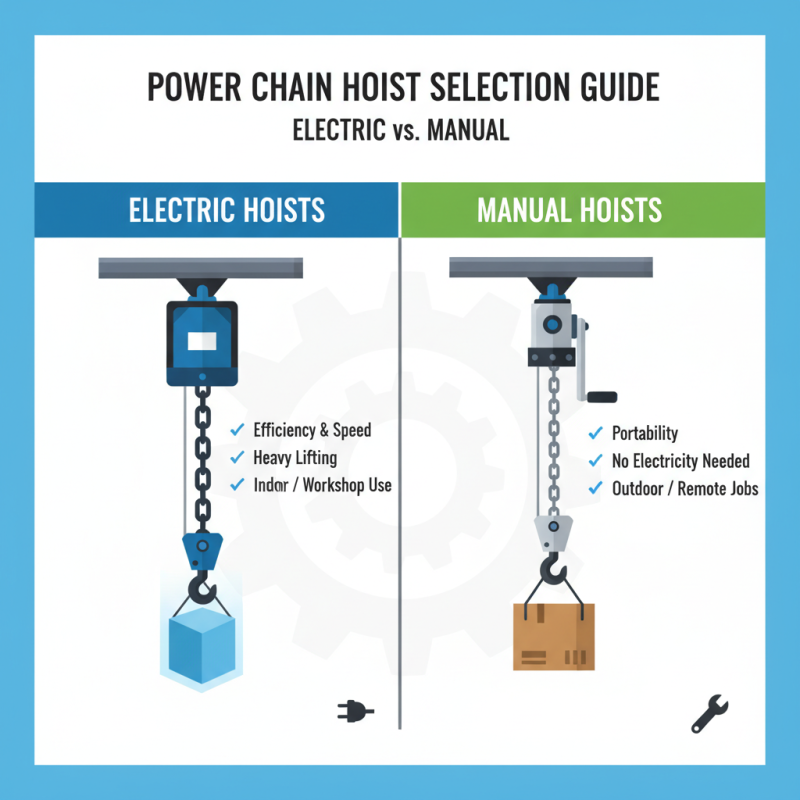

When selecting a power chain hoist, it’s essential to understand the different types available. Electric hoists are popular for their efficiency. They save time, especially in heavy lifting. Manual hoists, however, offer portability and reliability. They don't require electricity and are perfect for outdoor jobs.

Consider the load capacity before making a choice. Some hoists can lift over 10 tons, while others are designed for lighter loads. Safety features also vary. Chain brakes, limit switches, and emergency stops are important. These features can prevent accidents and ensure smooth operation.

Thinking about the environment is crucial too. Some hoists work better in specific conditions. For example, a dusty area may require a hoist with better protection. Reflecting on your specific needs is essential. Each choice has pros and cons. Evaluate your lifting tasks carefully.

When selecting a power chain hoist, understanding your load capacity requirements is crucial. Start by determining the maximum weight you plan to lift. This includes any equipment or materials attached to the load. Overloading a hoist can lead to accidents or equipment damage. For safety, always choose a hoist with a capacity that exceeds your needs.

Tips to consider: Check the hoist's specified load rating. Many hoists offer overload protection, but it’s not a guarantee. Factor in dynamic loads. These are the additional stresses that occur when lifting. User habits may also affect load capacity. Are you lifting consistently or sporadically?

It’s easy to assume a hoist can handle what you need. However, unexpected issues may arise. Reflect on your environment too. Will the hoist be used in confined spaces? Ensure the device can maneuver without restriction. Space constraints can alter your capacity calculations significantly.

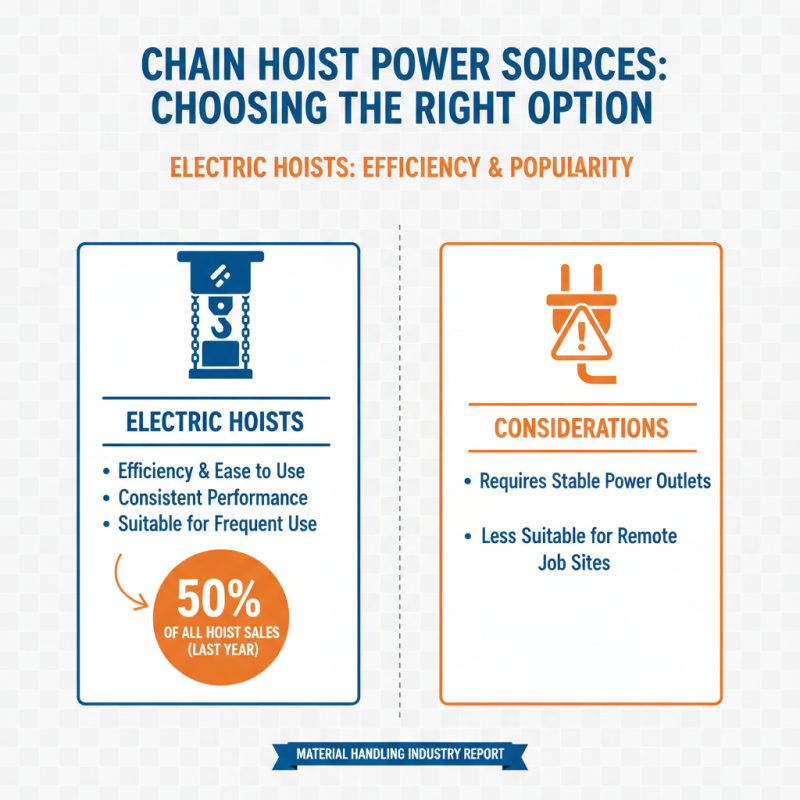

When evaluating power source options for chain hoists, it is crucial to understand the specific lifting needs of your application. Electric hoists are a popular choice due to their efficiency and ease of use. A report by the Material Handling Industry indicated that electric hoists account for nearly 50% of all hoist sales in the last year. Their consistency in performance makes them suitable for frequent use. However, they may require stable power outlets, which isn't always available in remote job sites.

On the other hand, pneumatic hoists offer unique benefits. They operate using compressed air, making them ideal for work environments with explosive hazards. According to data from the Industrial Truck Association, pneumatic hoists are gaining traction in areas where safety is a priority. However, their dependency on air supply can be a limitation; intermittent power issues can cause downtime and disrupt operations. Additionally, the cost of maintaining a compressed air system can add to long-term expenses.

Battery-operated hoists present a third option. They offer mobility and flexibility. With advancements in battery technology, modern hoists can operate longer than those from just a few years ago. A survey from the Occupational Safety and Health Administration revealed that using battery-operated equipment has increased safety ratings in various industries. However, charging times may hinder productivity, especially in high-demand environments. The balance between power sources requires deeper consideration based on your operational context.

When choosing a power chain hoist, safety features are crucial. You should prioritize hoists with overload protection. This feature prevents the device from lifting items that exceed its capacity. This can save equipment and prevent accidents.

Consider chain brakes as well. They offer additional security by stopping the load immediately if the control is released. You want to ensure that any load remains stable during operation. Look for models with emergency stop buttons too. These can instantly halt the hoist if something goes wrong.

Inspect the design for stability. A wide base can prevent tipping during operation. Look for hoists with safety hooks that have latches. These hooks keep loads secure, minimizing the risk of dropping materials. It’s wise to evaluate user reviews for insights on real-world safety performance. A fantastic model on paper may not be the safest in practice. Be mindful of these safety features to make informed choices.