Inquiry

Form loading...

-

E-mail

-

Whatsapp

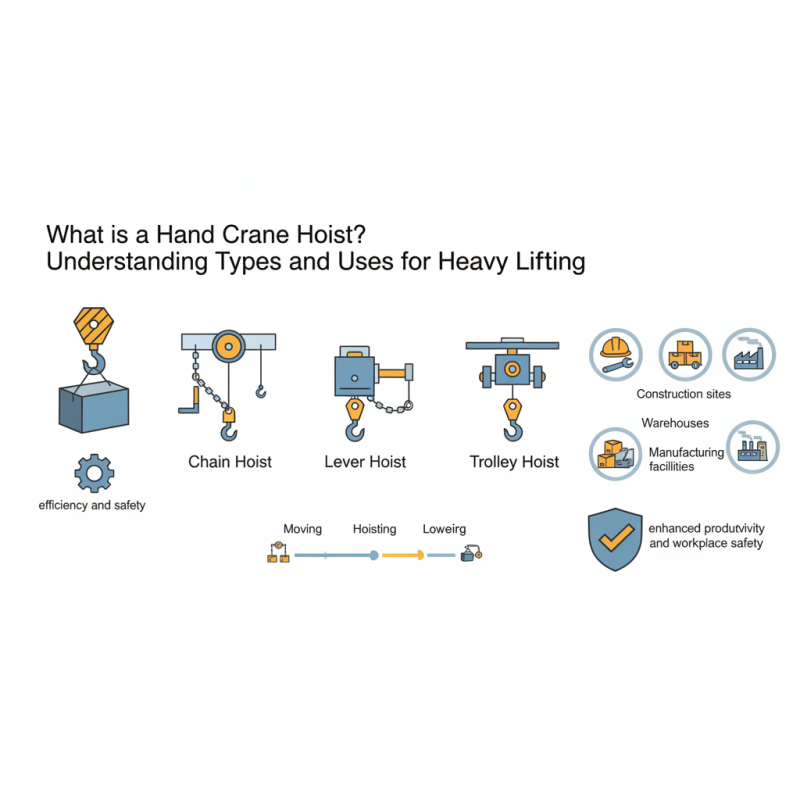

A Hand Crane Hoist is an essential tool in the world of heavy lifting, designed to simplify the process of moving, hoisting, and lowering heavy materials. These versatile devices come in various types, each tailored to meet specific lifting needs in different environments, such as construction sites, warehouses, and manufacturing facilities. Understanding the functionality and applications of Hand Crane Hoists is crucial for professionals who seek efficiency and safety in their operations.

The design of a Hand Crane Hoist typically integrates features that enhance its usability, such as easy maneuverability and sturdy construction. This makes it not only practical for one-time lifts but also ideal for repetitive tasks in demanding settings. By exploring the various types of Hand Crane Hoists and their respective uses, users can gain insights into the best practices for heavy lifting and the unique advantages that each type offers for specific applications.

In summary, a Hand Crane Hoist is more than just a lifting device; it is a vital component that facilitates various industrial activities. By delving into its types and uses, users can equip themselves with the knowledge required to make informed decisions that enhance productivity and ensure workplace safety.

A hand crane hoist is a mechanical device designed to lift and lower heavy objects safely and efficiently. Typically operated by hand, this equipment uses a system of pulleys and gears, enabling users to apply less force while lifting substantial loads. Hand crane hoists are versatile and can be utilized in various environments, including construction sites, workshops, and warehouses, making them essential for tasks that require lifting or moving heavy materials.

There are several types of hand crane hoists, each tailored to specific lifting needs. Manual chain hoists, for example, are preferred for their simplicity and cost-effectiveness, allowing users to lift loads by pulling a hand chain. In contrast, lever hoists provide a mechanical advantage, making it easier to lift heavier items with less effort. Additionally, these hoists can come with various features such as load limiters and safety hooks to enhance operational safety. Understanding these variations helps users select the most suitable hoist for their specific applications, ensuring both efficiency and safety in heavy lifting tasks.

Hand crane hoists are essential tools in various industries, particularly in construction, manufacturing, and warehousing, where heavy lifting is a daily requirement. These devices come in two primary variants: manual hoists and electric hoists. Manual hoists rely on human power to lift and lower loads, making them an economical choice for lighter duties or in locations where electricity is unavailable. According to industry reports, the manual hoist market is projected to grow by 6% annually, driven by the increased demand for efficient, low-cost lifting solutions.

Electric hoists, on the other hand, are powered by electric motors and are designed for heavier loads and more frequent use. They enable faster lifting operations while minimizing the labor intensity associated with manual variants. As per market analysis, electric hoists are anticipated to dominate the market due to their capabilities in handling loads up to several tons, ideal for large construction projects. This increase in efficiency can lead to reduced operational costs and enhanced safety protocols on job sites.

Tips: When choosing between a manual and electric hand crane hoist, consider the weight of the loads you regularly handle and the frequency of use. For infrequent, light tasks, a manual hoist may suffice; however, for regular, heavy lifting, investing in an electric model is advisable to improve efficiency and worker safety. Additionally, always adhere to the load capacity limits specified by the manufacturer to prevent accidents and equipment damage.

Hand crane hoists are essential tools in various industries for heavy lifting tasks. A basic understanding of their key components and mechanisms can help users appreciate their functionality and properly utilize them to enhance efficiency and safety in lifting operations. Generally, a hand crane hoist consists of a few critical parts: the hook, chain, lift mechanism, and the frame. The hook is designed to securely hold the load, while the chain facilitates lifting through the lift mechanism, which often includes gears and pulleys to ensure smooth operation.

The frame of the hand crane hoist provides the necessary stability and support, allowing for safe maneuvering during lifting. When selecting a hand crane hoist, it’s crucial to ensure that all components are well-maintained and inspected regularly. A reliable hoist not only enhances productivity but also minimizes the risk of accidents caused by equipment failure.

Tips: Always read the manufacturer’s instructions to familiarize yourself with the specific features of your hoist. Additionally, consider load limits and ensure that the load is evenly distributed to prevent tipping or swaying during lifting. Regular maintenance, such as lubricating moving parts and checking for wear and tear, is vital for ensuring optimal performance and longevity of the hand crane hoist.

Hand crane hoists are essential tools utilized across various industries for lifting and transporting heavy objects. These devices leverage mechanical advantage, allowing operators to safely move items that would otherwise be too cumbersome to handle manually. Hand crane hoists find applications in construction, manufacturing, and maintenance. For example, in the construction industry, they assist in lifting beams and materials to high levels, while in manufacturing, they are vital for moving heavy components along assembly lines.

In maintenance operations, these hoists are particularly useful for tasks involving heavy machinery or equipment upkeep, allowing quick and efficient access to hard-to-reach areas. Tips for using hand crane hoists effectively include ensuring that the load is balanced and securely attached to prevent accidents. Additionally, regular inspection of the hoist for wear and tear is crucial for maintaining safety standards.

Another practical tip is to familiarize yourself with the specific weight limits and features of the hoist being used. This knowledge helps in selecting the right equipment for the job, ensuring efficiency and preventing equipment failure. Overall, hand crane hoists play a significant role in enhancing productivity and safety across various sectors.

| Type of Hand Crane Hoist | Load Capacity | Common Uses | Industries |

|---|---|---|---|

| Manual Chain Hoist | 0.5 to 10 tons | Lifting heavy equipment, assembly work | Manufacturing, Construction |

| Electric Chain Hoist | 0.5 to 20 tons | High-frequency lifting tasks, automation | Logistics, Warehousing |

| Lever Chain Hoist | 0.75 to 9 tons | Lifting in tight spaces, portability | Construction, Automotive |

| Pneumatic Hoist | 0.5 to 5 tons | Lifting in hazardous environments | Aerospace, Petrochemical |

| Mini Electric Hoist | 0.1 to 1 ton | Small-scale lifting tasks | Home use, DIY projects |

When using hand crane hoists, safety should always be the top priority. Proper training and understanding of the equipment are crucial to prevent accidents and injuries. Before operating a hand crane hoist, ensure that you are familiar with its specific features and functionality. Additionally, conduct a thorough inspection of the hoist, checking for any signs of wear or damage that could compromise its performance.

Tips for Safety: Always wear appropriate personal protective equipment (PPE), including gloves and hard hats, to minimize the risk of injury. Keep the lifting area clear of obstacles and unauthorized personnel, as this can help prevent accidents during operation. It's also advisable to establish a clear communication system with all team members involved in the lifting process to ensure everyone is aware of the actions being taken.

Moreover, calculate the weight of the load to be lifted and never exceed the hoist's capacity. Distributing the load evenly and using adequate rigging can enhance stability and prevent tipping or swinging during the lift. Remember to follow established lifting protocols and always remain aware of your surroundings to maintain a safe working environment.