Inquiry

Form loading...

-

E-mail

-

Whatsapp

Operating a trolley crane requires precision and care. John Smith, a veteran in the industry, states, "Safety is the backbone of crane operation." This emphasizes the importance of prioritizing safety in every lift. Trolley cranes are valuable assets in construction and manufacturing. However, their operation can pose risks if not handled correctly.

Proper training is essential for operators. They must understand the mechanics of the trolley crane and its load limits. Familiarity with the environment plays a key role in preventing accidents. For instance, objects overhead can pose significant hazards. Moreover, wind conditions must be considered, as they can affect stability.

Unfortunately, some operators overlook these details. This negligence can lead to accidents and injuries. Regular inspections of the trolley crane equipment should not be neglected. Operators should maintain awareness of their surroundings. Continuous improvement and reflection on past operations are necessary for achieving a safe workplace.

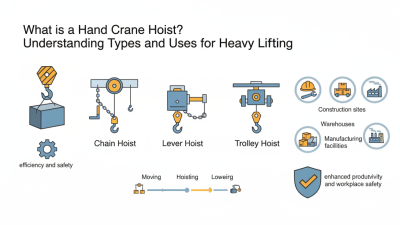

Trolley cranes are essential for lifting heavy loads. Understanding their basic components is crucial for safe operation. A sturdy frame supports the crane. The trolley moves along a rail, providing flexibility. The hoisting mechanism lifts and lowers materials. Operators should familiarize themselves with each part to enhance safety.

Tips: Always check equipment before use. Look for wear and tear. Ensure all components are functioning properly. This practice can prevent accidents and equipment failure.

Practicing proper rigging techniques is vital. Use the right slings and hooks based on the load type. Improper rigging can lead to loads shifting or falling. Consider the weight distribution during lifting. This helps maintain balance and stability. Tighten your understanding of these concepts. It can save lives.

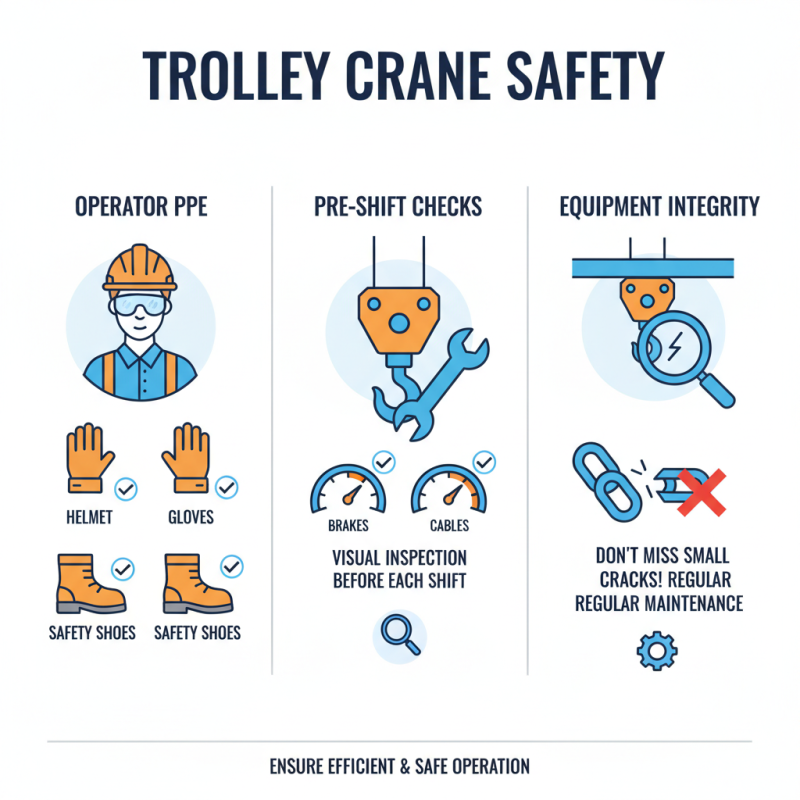

Operating a trolley crane involves specific safety regulations and standards to ensure efficient functioning. To begin with, operators must wear appropriate personal protective equipment. This includes helmets, gloves, and safety shoes. Regular checks on equipment integrity, like brakes and cables, are essential. A visual inspection should occur before each shift. Missing a small crack can lead to failure.

Training is a crucial piece. All operators should undergo rigorous training sessions. Familiarity with the crane's controls is vital. Operators often overlook minor details, which can cause accidents. Clear communication signals between team members can prevent confusion and mishaps.

Compliance with local and national regulations is non-negotiable. The lack of adherence can pose serious risks. Operators must stay updated on safety standards. They should review operational manuals and refresh their knowledge regularly. In the fast-paced environment of construction sites, mistakes can happen. Reflecting on past errors is necessary for improvement. Safety should never be taken for granted.

Operating a trolley crane requires careful attention to safety and efficiency. A successful operation begins with thorough pre-operative checks and inspections. Industry reports indicate that nearly 60% of crane accidents are due to human error. Regular safety checks can significantly reduce these risks. Inspecting the crane’s brakes, hook, and wire rope should be routine. Each component plays a vital role in ensuring safe lifting operations.

Before starting, conduct a walk-around inspection. Look for any signs of wear and tear. Pay attention to loose bolts or frayed cables. These small details can prevent major accidents. In addition, operators should be aware of local weather conditions. High winds can be particularly hazardous for crane operations. Always check the wind speed before lifting.

Operating a trolley crane safely and efficiently requires attention to detail. Good maneuvering is key to minimizing risks. Before starting, inspect the crane for any wear or damage. This simple step can prevent accidents later.

When moving loads, keep them as low as possible. This lowers the center of gravity and enhances stability. Always communicate clearly with team members. Use hand signals or radios to ensure everyone knows the plan.

Tips: Adjust the speed of the crane based on load weight. Heavier loads require slower movement. Always be aware of your surroundings. Avoid areas with obstacles or overhead hazards. Remain vigilant, even when the crane is idle. Stay focused on your tasks, and do not let distractions compromise safety.

This chart depicts the best practices for operating a trolley crane safely and efficiently, focusing on key performance metrics such as Load Handling Efficiency, Operator Training Hours, and Safety Incident Rate over a year.

Operating a trolley crane requires careful attention to safety and maintenance. Emergencies can happen anytime, making it essential to be prepared. For example, if a power failure occurs, operators must know how to lower the load safely. Familiarizing yourself with emergency shutdown procedures is critical. Always keep an updated checklist of these procedures handy.

Routine maintenance plays a vital role in ensuring operational efficiency. Inspecting the crane daily is a standard practice. Check for loose bolts and damaged cables. Lubricate moving parts regularly. Small issues can lead to significant problems if ignored. Remember, a well-maintained crane is safer and more reliable.

It’s easy to overlook minor details when operating heavy machinery. Always follow safety protocols closely. Be aware of your surroundings and potential hazards. Encourage team communication. Discuss any safety concerns openly. Effective communication can prevent accidents. A collaborative approach boosts workplace safety. Safety is a shared responsibility.