Inquiry

Form loading...

-

E-mail

-

Whatsapp

Electric Scissor Lift Tables are essential in various industries. They provide safe and efficient solutions for reaching elevated workspaces. However, improper use can lead to accidents and injuries. Safety is paramount when operating these powerful tools.

Understanding the features of Electric Scissor Lift Tables is crucial. Operators must be aware of weight limits and platform heights. Regular maintenance checks can prevent equipment failure. Ignoring these practices can result in serious risks.

It’s important to train all personnel. Inexperienced operators may overlook safety protocols. Observing best practices ensures a safer working environment. However, even with training, accidents can happen. Reflecting on past mistakes can improve future performance. Awareness and preparation are key.

Electric scissor lift tables can greatly improve productivity in various industries. However, safety should always be a top priority. Understanding safety standards is crucial. Many guidelines outline how to operate these tables without risks. Compliance can prevent accidents and injuries. Familiarize yourself with local regulations before using any equipment.

Before operating the lift table, inspect it carefully. Look for visible defects or malfunctions. Test the emergency stop function each time. This quick step can save lives. Always ensure that the area around the lift is clear. Obstacles can be dangerous during operation. Also, do not exceed the load capacity. It might be tempting to push limits, but this can lead to serious accidents.

Training is essential. Workers should be educated on proper operating procedures. Knowledge of safety features is equally important. Regular refresher courses can be useful. Encourage everyone to report unsafe conditions. Ignoring issues is never an option. Maintaining a culture of safety can lead to better outcomes. Always remember, safety is everyone's responsibility.

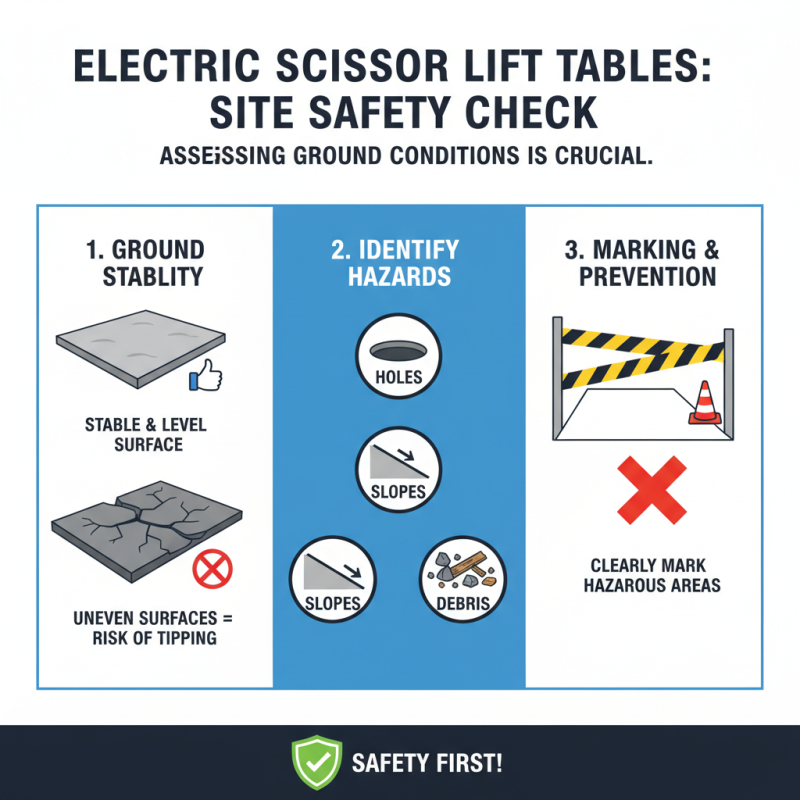

When using electric scissor lift tables, assessing site conditions is crucial for safety. Start by examining the ground surface. It should be stable and level. Uneven surfaces can lead to tipping or accidents. Look out for holes, slopes, or any debris that may pose a risk. Mark hazardous areas clearly.

Consider the overhead environment as well. Check for power lines, overhead structures, or any obstructions. These could interfere with the lift's operation. It's also wise to monitor weather conditions. High winds or rain can make operations dangerous. Operators may overlook these factors, but neglecting them can lead to serious issues.

Don’t forget to think about space. Ensure there is enough room for the lift to operate freely. Tight spaces can limit movement. A clear area promotes a safer working environment. It's essential to communicate with your team about site conditions. Sharing insights can prevent accidents and improve overall safety awareness.

Proper training is essential for electric scissor lift operators. According to the Occupational Safety and Health Administration (OSHA), falls account for over 30% of workplace fatalities. Without proper training, operators may not fully understand the risks associated with operating lift tables. This can lead to dangerous situations and accidents.

Training programs should cover crucial topics such as pre-use inspections, load limits, and emergency protocols. A report by the National Institute for Occupational Safety and Health (NIOSH) indicates that operators who receive comprehensive training are less likely to experience accidents. Yet, many workplaces overlook this requirement.

Moreover, hands-on training is vital. Operators need to practice maneuvering the lift under various conditions. Thus, practical training ensures that operators can adapt to unexpected challenges. Real-life scenarios prepare them better. However, some programs fail to provide this vital experience. This gap can lead to confusion when it matters most. Addressing these gaps in training is critical for enhancing safety on the job.

| Tip Number | Safety Tip | Description | Training Requirement |

|---|---|---|---|

| 1 | Pre-Use Inspection | Inspect lift for any damage or malfunctions. | Operator Training in Equipment Inspection |

| 2 | Safety Gear | Wear proper personal protective equipment. | PPE Training |

| 3 | Load Capacity | Do not exceed the lift's weight limit. | Load Management Training |

| 4 | Stability | Ensure the ground is level before operation. | Site Assessment Training |

| 5 | Weather Conditions | Avoid using lifts in extreme weather. | Weather Safety Training |

| 6 | Proper Training | Only trained operators should use lifts. | Lift Operation Training |

| 7 | Emergency Procedures | Know what to do in case of an emergency. | Emergency Response Training |

| 8 | Communication | Maintain clear communication with ground crew. | Communication Protocol Training |

| 9 | Avoid Crowds | Keep bystanders at a safe distance. | Site Safety Training |

| 10 | Post-Use Procedures | Properly secure the lift after use. | Post-Operation Training |

Electric scissor lift tables can be very useful. However, they come with their own set of hazards. One major risk is falling from heights. Workers must wear harnesses to prevent accidents. Proper training is essential. Everyone should know how to operate the lift safely. Without proper understanding, the risk of injury increases.

Another common hazard involves electrical issues. Loose wires can create a shocking situation. Regular inspections are necessary. Check for frayed cables or malfunctioning controls. If something seems off, do not use the equipment. Report it immediately for repairs.

Lastly, ensure the area around the lift is clear. People often forget to check for overhead obstacles. Equipment or low-hanging beams can be dangerous. Take a few moments to assess the environment. A clear workspace significantly reduces risks. Reflection on these hazards can lead to better safety practices. Awareness is key.

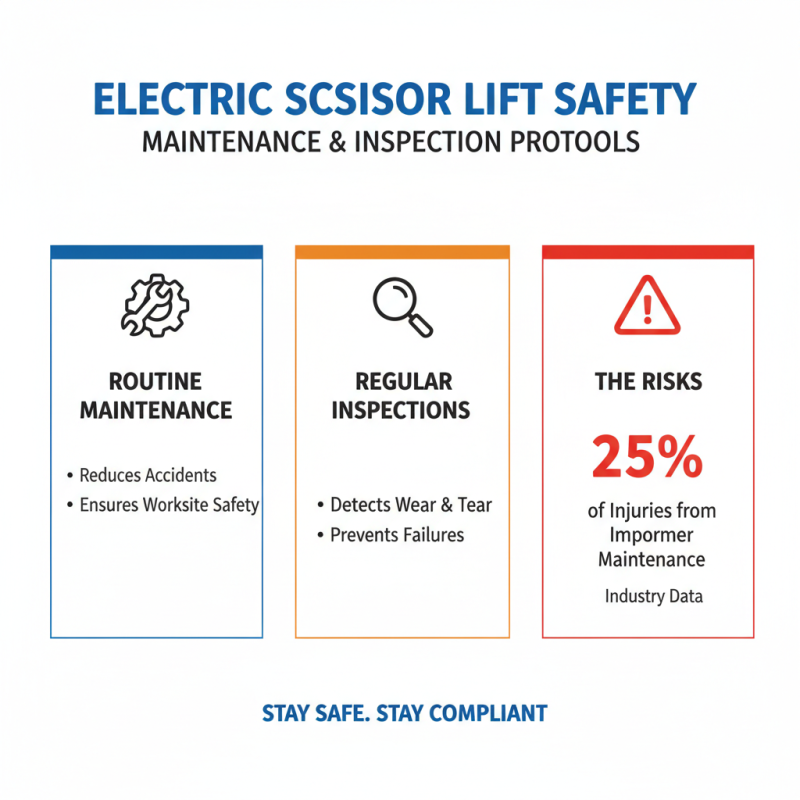

Routine maintenance and inspection protocols for electric scissor lifts are critical for ensuring safety on work sites. Regular checks can reduce the likelihood of accidents. According to industry surveys, improper maintenance contributes to nearly 25% of lift-related injuries. Elevated work platforms must undergo rigorous inspections to detect wear and tear.

Perform daily inspections before use. Check the lift’s hydraulic system for leaks. Examine the battery and cables for any signs of damage. Ensure that the safety features, such as emergency controls, are functioning. Remember, regular maintenance keeps operators safe and prolongs equipment life.

Implement a proactive maintenance schedule. This includes monthly checks of electronic components and structural integrity. Inspect tires for wear and proper inflation. Neglecting these tasks can lead to costly repairs and increase the risk of hazardous incidents. Always document inspections and maintenance activities. This ensures compliance and can reveal patterns that indicate deeper issues. Stay vigilant and informed.