Inquiry

Form loading...

-

E-mail

-

Whatsapp

In the construction industry, efficiency is paramount. "Scaffold Hoists" play a crucial role in enhancing productivity on job sites. As construction expert John Anderson once stated, “The right equipment makes all the difference.” This sentiment resonates deeply in today's fast-paced projects.

Selecting the best scaffold hoists is vital for safety and speed. With numerous options available, it can be overwhelming. Crafting a strategy that includes the right hoist can streamline workflows. However, not every choice is foolproof. Some hoists may underperform or lead to safety hazards if not properly evaluated.

Understanding the limitations of various models is essential. Each hoist operates differently based on design and load capacity. Compromising on quality can lead to costly delays. Investing time in research and consideration is key to avoiding mistakes. Ultimately, the best scaffold hoists are those that fit the project requirements while ensuring worker safety.

Scaffold hoists play a critical role in construction projects. These machines simplify the transport of materials and workers to various heights. According to industry reports, effective material handling can reduce project timelines by up to 30%. In construction, time is money, and hoists help save both.

Understanding the importance of scaffold hoists helps in choosing the right model. The right hoist can increase productivity significantly. A study found that nearly 45% of accidents in construction occur during material handling. Using reliable scaffolding equipment minimizes these risks. Poorly chosen hoists can lead to injuries and project delays.

Yet, there are challenges. Many workers lack proper training in operating these machines. A report indicated that inadequate operator skills are a common cause of mishaps. Investing in training can enhance safety and efficiency. The importance of robust safety protocols cannot be overstated. Choices made in selecting scaffold hoists can define the entire project's success.

When selecting a scaffold hoist, several factors deserve careful consideration. First, assess the weight capacity needed for your project. A hoist must handle the materials without strain. Consider the height you need to reach. This affects the type and power of the hoist. The height also impacts the safety measures required.

Next, think about the power source. Electric hoists are more efficient but require access to power. Manual hoists may be simpler but could lead to fatigue. Check the material of the hoist. Steel frames offer durability, while aluminum reduces weight but may not be as strong. It’s important to ensure that the hoist fits your construction site.

Transportation and storage are other key aspects. Some hoists can be bulky, making them hard to move. Look for designs that are easy to assemble and disassemble. Also, consider the safety features. Emergency brakes and stability controls can prevent accidents. Each construction project has unique needs, and a one-size-fits-all approach may lead to mistakes. Reflect on these details during your choice.

When it comes to scaffold hoists, choosing the right model can significantly impact construction efficiency. Many hoists come with essential features, such as load capacity and height reach. A robust hoist can lift heavy materials quickly, saving vital time on site. However, it's crucial to consider the weight limit. Exceeding this can cause safety issues.

Specifications vary widely among different hoists. For instance, some models have a maximum height of over 100 feet. Others focus on more compact designs for tighter spaces. Understanding these differences can lead to better project outcomes. Yet, many overlook the importance of power source options. Electric hoists provide consistent performance, while manual hoists require more physical effort, which could slow progress.

Benefits of using scaffold hoists are apparent. They enhance workflow by minimizing manual labor. This can lead to reduced fatigue among workers. Properly selected hoists can also promote better safety standards. Still, some projects may find logistics challenging. Transporting bulky equipment can complicate scheduling. It's essential to plan accordingly to avoid delays, reflecting on the logistical aspects is crucial.

| Model | Load Capacity (lbs) | Lift Speed (ft/min) | Max Height (ft) | Power Source | Weight (lbs) | Key Features |

|---|---|---|---|---|---|---|

| Model A | 800 | 40 | 200 | Electric | 150 | Lightweight, Easy Installation |

| Model B | 1000 | 30 | 250 | Gas | 200 | High Load Capacity, Durable |

| Model C | 600 | 50 | 180 | Battery | 120 | Portable, Rechargeable |

| Model D | 750 | 35 | 220 | Electric | 160 | Compact Design, Easy to Transport |

| Model E | 900 | 45 | 240 | Gas | 190 | Reliable, High Efficiency |

| Model F | 650 | 38 | 160 | Battery | 140 | User Friendly, Quick Setup |

| Model G | 850 | 48 | 230 | Electric | 170 | Versatile, Safety Features |

| Model H | 1000 | 30 | 300 | Gas | 210 | Heavy Duty, Towing Kit |

| Model I | 700 | 60 | 210 | Battery | 130 | High Speed, Eco-Friendly |

| Model J | 600 | 55 | 190 | Electric | 125 | Cost-Effective, Robust Design |

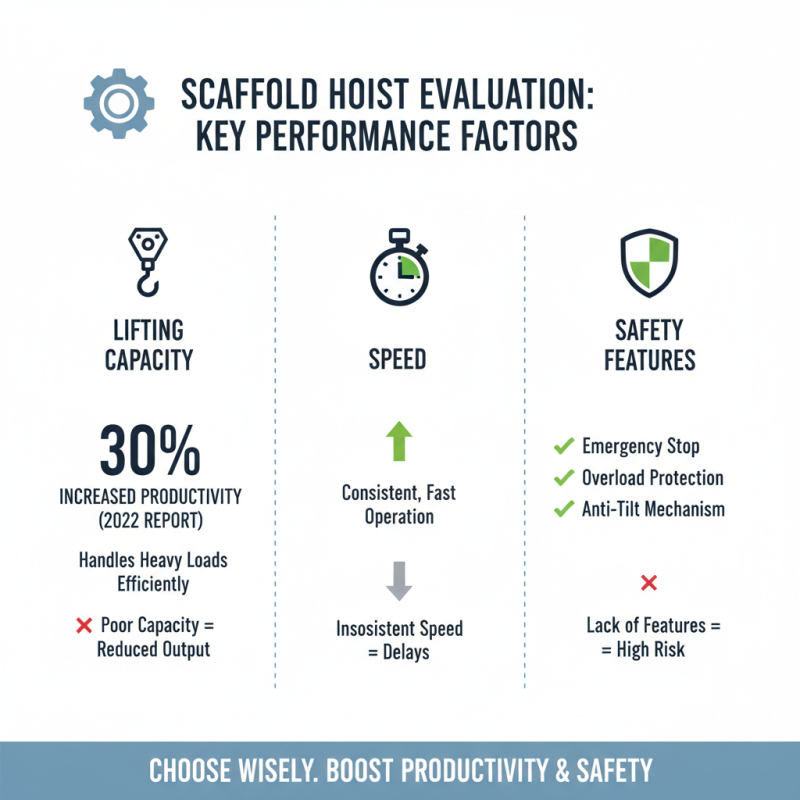

When evaluating scaffold hoists, it's crucial to consider key performance factors. Performance metrics commonly include lifting capacity, speed, and safety features. A 2022 industry report indicated that efficient hoists can increase productivity by up to 30%. However, not every hoist delivers on these metrics. Some models struggle with inconsistent speed or poor lift capacity under heavy loads.

Safety is a major concern in the construction industry. A survey revealed that 40% of users reported safety-related issues with their hoists. This includes failures in emergency braking systems. Choosing a reliable hoist means understanding these risks. Many brands offer safety ratings, but actual performance can vary widely in real-world scenarios.

Durability is another pressing issue. A significant percentage of scaffold hoists don’t withstand harsh environmental conditions. Corrosion and wear can lead to equipment failure. It's essential to select hoists designed for specific conditions. Take the time to research and analyze brand claims against actual field data. User reviews often provide insights into long-term performance and potential issues.

Safety is paramount when using scaffold hoists on construction sites. Operators must undergo thorough training to understand the equipment's capabilities and limitations. Even experienced workers can overlook safety checks due to rushing or distractions. Proper inspection before each use is essential. This includes checking cables, pulleys, and safety locks. Neglecting these checks can lead to serious accidents. Always ensure the area below is clear of personnel and obstacles.

Using personal protective equipment (PPE) is a must. Hard hats, gloves, and non-slip footwear help keep workers safe. But it’s crucial to have a plan for emergencies. What if a worker falls? What steps should be taken? Developing a clear response plan can make a difference. Communication among the team is key. Everyone should know their roles in both daily operations and emergency situations.

Additionally, be mindful of weather conditions. Strong winds can make working with scaffold hoists dangerous. Rain or ice can create slippery surfaces. Workers must adapt their practices accordingly. Even the best equipment cannot replace common sense. Reflecting on past incidents can guide improvements. Safety in construction is an ongoing journey, not a destination.

This chart illustrates the load capacities of the top 10 scaffold hoists commonly used in construction projects, showcasing their efficiency and suitability for various tasks. Safety considerations should be made based on the load capacity indicated for each hoist.